SIZE & PERFORMANCE

MECHANICS

|

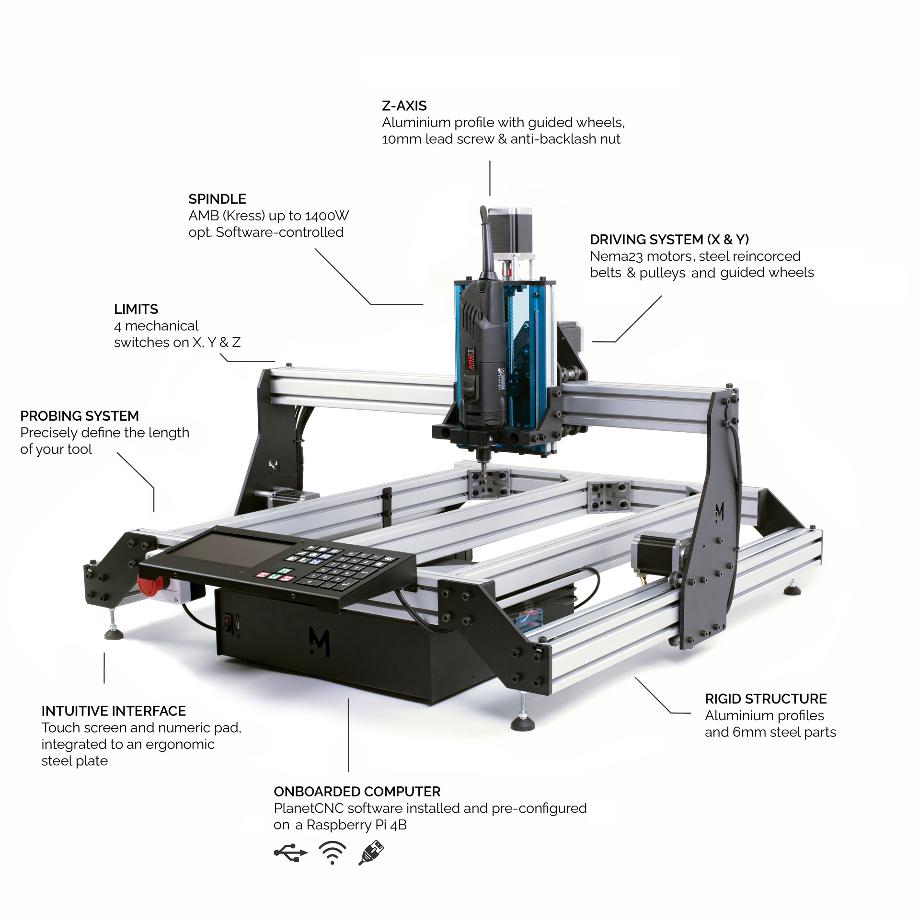

Structure

|

- Steel plates (6mm) - Aluminium profiles (30x60mm & 60x60mm) |

| Linear guide system | V-slot wheels |

| Drive System |

|

| X and Y-Axis | - Steel-reinforced PU GT2 belts - GT2 20T 6mm pulleys |

| Z-Axis | - T8 Trapezoidal leadscrew - Anti-Backlash nut |

ELECTRONICS

|

Motors

|

Nema23, 2 A (4x) |

|

Motor drivers

|

- 24 VDC, 2.5 A - Microstepping 1/32 |

| Embedded computer | Raspberry Pi 4 - 2 GB RAM |

| Ports | - 3 USB ports - 1 Ethernet port - 1 HDMI port |

| Connectors | - Neutrik XLR (motors and sensors) - GX12 (inputs/outputs) |

| Interface Unit | - 7" TFT IPS capacitive touchscreen - Custom Bluetooth keypad |

| Connectivity | - WiFi (2.4 GHz and 5.0 GHz IEEE 802.11ac ) - Bluetooth (5.0) - Gigabit Ethernet |

| Limits Sensors | High-precision microswitch (4x) |

| Tool length sensor | Touch plate with crocodile clip |

|

Controller

|

PlanetCNC Mk3/4 |

CONTROL SOFTWARE

|

PlanetCNC TNGv2

|

- Embedded G-code generator/editor - Toolpath visualization - Import toolpath from 2D files (dxf, png,...) - Advanced motion interpolation - Simulation mode - Manual Data Input mode (MDI) - Automatic homing and square gantry - Automatic tool length measuring and probing - Feed & speed override - Customizable view, scripts and M-codes |

| CAM compatibility | Compatible with all CAM software available on the market (advising Fusion360) |

SAFETY

|

Spindle

|

DI spindles will automatically stop when an emergency stop button is pressed or a milling program is finished. This limits the time when a sharp endmill is spinning to a minimum. DI spindles are optional products. |

| Enclosure | The enclosure offers a safe environment around the CNC in which nothing can enter while the CNC is running. The doors are monitored and their opening will automatically cause an emergency stop of the machine and DI Spindle. The enclosure is an optional product. |