With this guide, discover how to use your DXF or STEP files and convert them. We deal with most frequent issues faced when learning CNC milling.

Roldan D.

Sales & Marketing

Every discipline has its share of acronyms of questionable relevance and clarity, and digital milling is no exception.

Fortunately, the number of capital letters to remember in this discipline remains relatively limited.

Here's a quick overview.

CNC stands for “Computer Numerical Control”, and refers to a manufacturing method based on the automation and precise control of machine tool movements through the use of pre-programmed computer software integrated into these tools.

By extension and in a more familiar way, the three letters used as a name often designate all machines capable of carrying out machining operations on the basis of a 2D or 3D model previously prepared via a computer.

To refer to “a CNC” is therefore generally to designate a digital milling machine (also commonly referred to as a “CNC milling machine” or “CNC machine”), as this is the most widespread machine using this machining process.

Despite this widespread abuse of the term today, this manufacturing technique is used in many other modern tools, such as 3D printers, CNC lathes, laser...

The acronym for “Computer-Aided Design” refers to the stage of modeling a part using a computer.

This is the point at which the original design of your project is digitized so that (among other things) it can be used as the basis for machine instructions in the CAM stage.

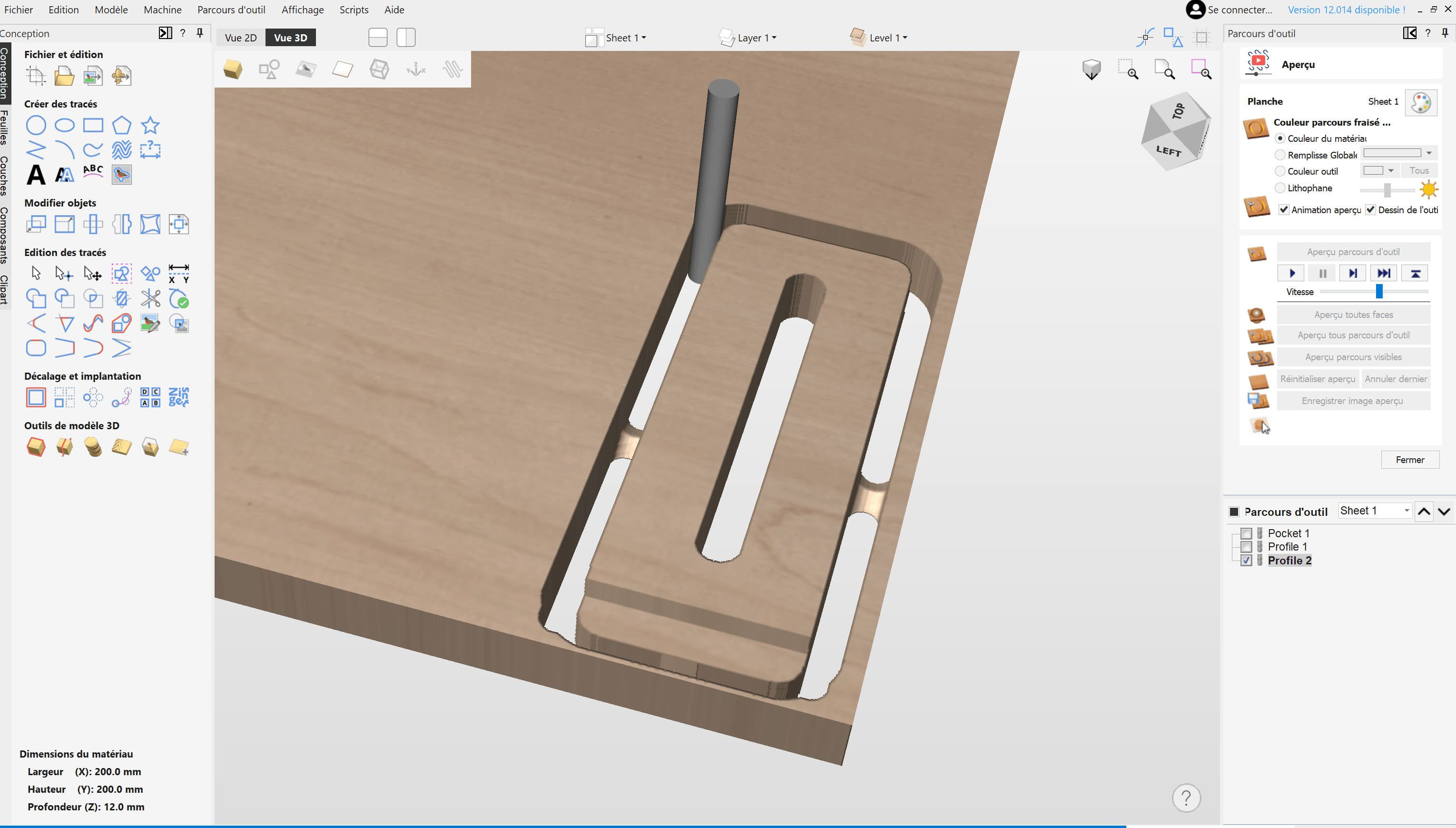

The acronym for “Computer-Aided Manufacturing” refers to the process of defining the machining operations for a part.

In concrete terms, starting from the part modeled during the CAD phase, we generate the machining instructions to be used by the machine, taking into account its technical characteristics, its accessories (milling cutters, laser, etc.) and the material to be worked.

Please refer to our article on CNC softwares to learn more about the main CAD/CAM programs.

Are you still a little lost in the world of CNC?

t's only natural when you start from scratch. The good news is that there are a lot of different ways to start your journey!

Check out our blog article about the best ways to learn about CNC milling or directly book a seat for one of our online CNC training session.

Mekanika is a Belgian company based in Brussels whose ambition is to make local production more accessible thanks to a 100% open-source approach.

We design and produce high quality machines for CNC milling and screen printing, which have been recognized for their reliability and ease of use. Our tools are delivered as kits and fully documented, allowing to easily adapt them to specific needs.

Visit our shop to find out more, or check out our online resources and tutorials to continue learning.

With this guide, discover how to use your DXF or STEP files and convert them. We deal with most frequent issues faced when learning CNC milling.

Roldan D.

Sales & Marketing

Learn how to create your project and generate G-Code from VCarve Pro or Aspire to easily machine your parts on a CNC milling machine.

Xavier K.

CNC Training

Hot engraving, cold engraving, tools and tutorials: everything you need to know about wood engraving with your CNC machine.

Quentin L.

Content Creation