What You Can Use it For

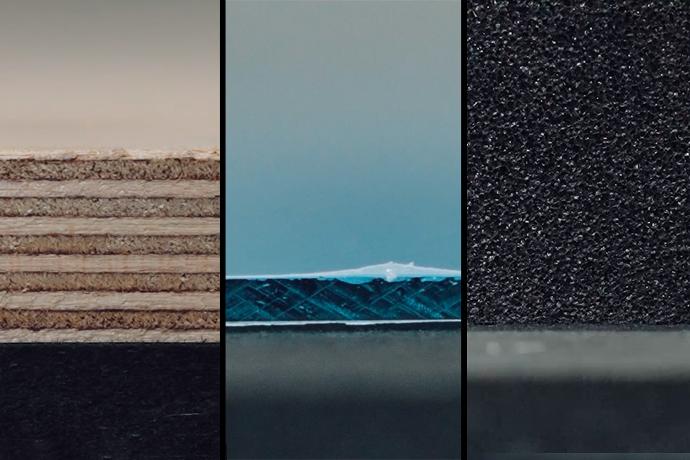

Large range of compatible materials

Our vacuum table is compatible with a wide range of materials, as long as they have flat surfaces.

Wood, sheet metal, plastic plates, foam... you name it!

Large range of compatible size

This is probably the most unique feature of this vacuum table. It will allow you to attach a wide range of panel sizes without any setup modification. All the way from a full panel sheet down to a 200x200mm stock, your pieces are securely attached.

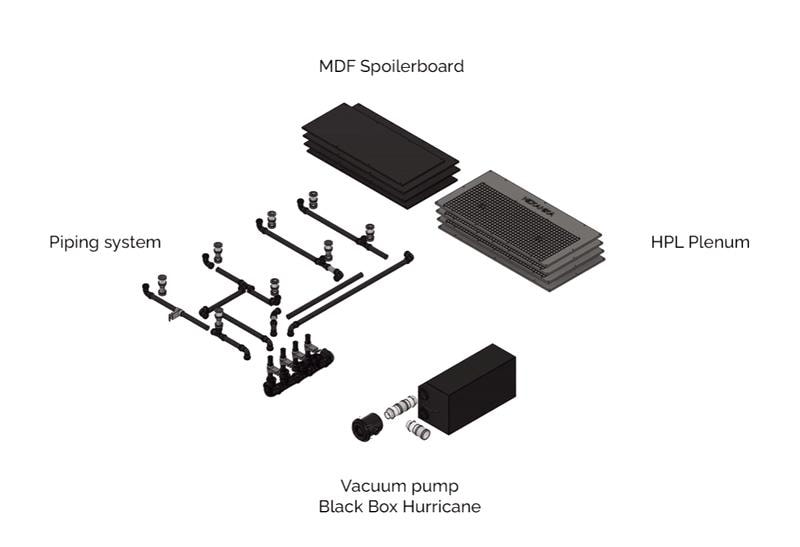

Kit Content

Complete Setup

Our complete setup is composed of:

- A hurricane Blackbox Vacuum Pump

- Robust 20mm HPL panels as table base

- A complete piping system with valves

- An MDF spoilerboard adapted to your Fab

It includes everything you need to setup a fully functional vacuum table.

Electrical Installation Requirements

DISCLAIMER:

To safely use the vacuum pump, your electrical installation must include a 32A circuit breaker and (2+G) x 6mm² cables (such as the XGB 3G6 for instance). Please ensure any electrical work is carried out by a qualified professional to avoid injury or damage.

Important Installation Information:

1. Electrical Requirements:

This vacuum pump requires a power supply that can handle a 30A electrical current. To ensure safety and proper operation, it is necessary to have a 32A circuit breaker installed. Additionally, your wiring should be 6.0mm² in diameter to support this level of electrical current.

2. Pre-Installation Recommendations:

We include all the necessary sockets in our kit and you will receive wiring instructions.

Note: if you wish to prepare your installation ahead of time, you can purchase compatible sockets separately. If you're not sure on how to proceed with the electrical installation, we recommend consulting with a qualified electrician for the installation. For a secure and compatible connection, consider purchasing the following socket types:

- IEC 60309 (32A, 2P+E, 230V): Commonly used for industrial applications, this type of socket is designed to handle high current loads safely.

- NEMA L6-30R (30A, 250V): This twist-lock socket is popular in North America and ensures a secure connection for high-power equipment.