Material

Operating at the intersection of old and new, Timelab combines traditional textile materials for spinning and weaving with contemporary manufacturing materials. Their projects utilize both natural fibers for traditional techniques and modern materials for their innovative tool development.

Working environment

Timelab's workspace functions as a dynamic hub where multiple projects coexist, from textile innovation to sustainable industry development and cultural space transformation. Their critical makerslab hosts collaborations with various institutions including K.A.S.K.'s Soft Connection lab, VUB engineering, and Design Academy Eindhoven, fostering cross-disciplinary innovation through workshops, summer camps, and ongoing projects.

Product

Timelab develops open-source machinery and tools for textile production, with a focus on making traditional techniques accessible through modern technology. Their flagship development is an innovative open-source loom created in collaboration with the Industry Museum in Gent, Belgium, designed to be reproducible and adaptable for various textile applications.

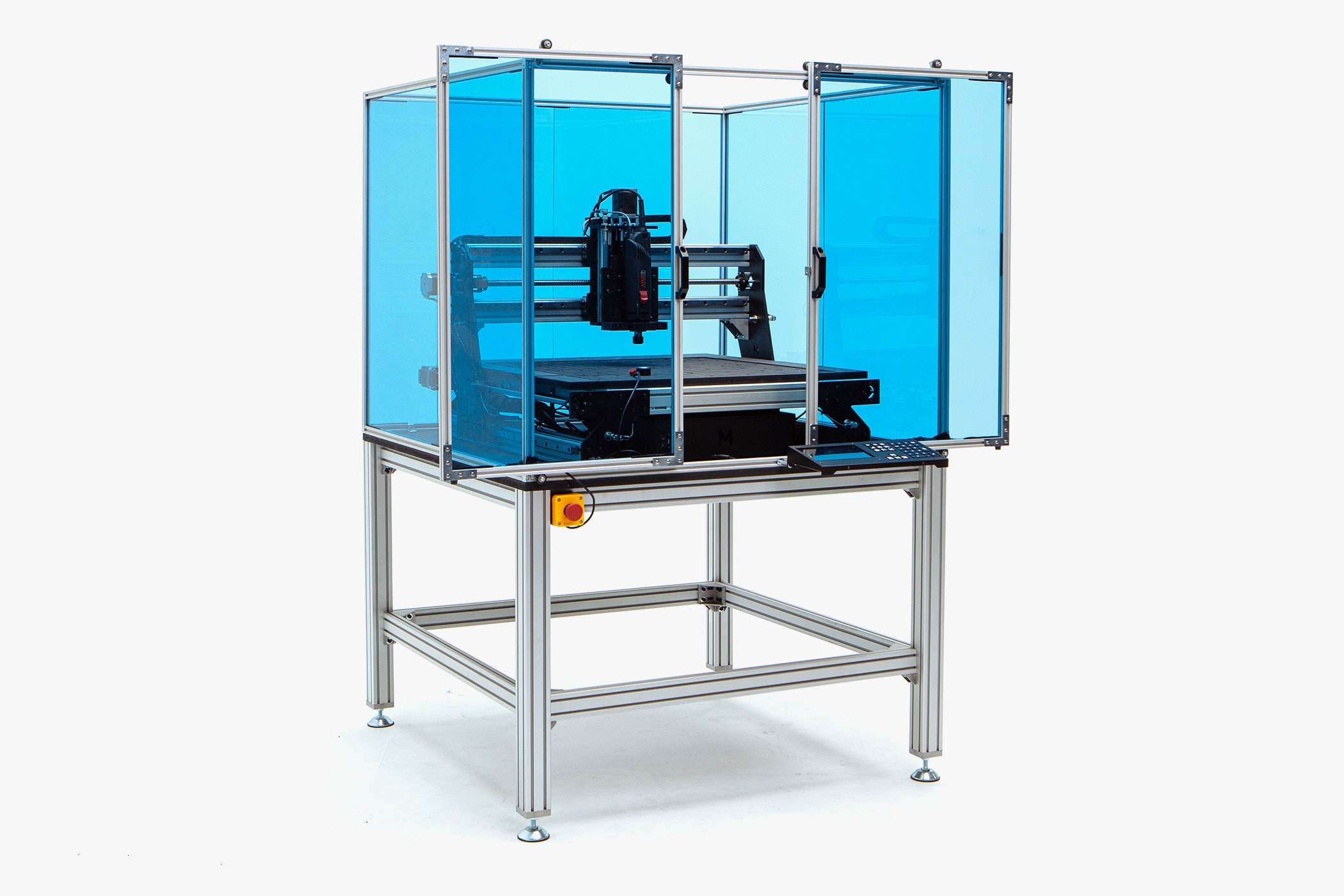

Machine setup

Timelab's Mekanika Pro-L CNC milling machine serves as a cornerstone of their prototyping and production capabilities. This precision machine enables them to create custom components for their textile tools with high accuracy and repeatability, essential for developing and improving their open-source equipment designs.

Discover our Education Packs

Safety first!

Whether you are interested in the Mekanika Pro or Evo, if you are planning to purchase a machine for a school or a collective, we recommend that you have a look at our Education Packs.