Typical Workflow

Plug-and-play Installation

Install the interface plate and the docking station, plug the cables and you can start! Simply attach the laser head to the magnetic docking station, it will automatically align and be powered up.

When you've finished using the laser, simply remove it and place the protective cover on the docking station, making sure it's dust-free from the milling operations that will be carried out on your CNC machine.

A Unified Workflow

Experience the easy integration of this new laser functionality into your familiar workflow. Use the same user-friendly interface and software you're accustomed to with your spindle. Transitioning between milling and laser operations is as simple as the push of a button.

Focal length adjustment is also very simple: you can use the same tool measurement probe supplied with your CNC machine. No need to slowly jog the Z-axis and manually check with a height gauge.

Regarding the G-code, while you have the flexibility to use any CAM software of your choice, we recommend using the free Opt-lasers G-code generator for cutting and line engraving. For those seeking more advanced engraving capabilities, we recommend using Lightburn that also gives great results.

Application Examples

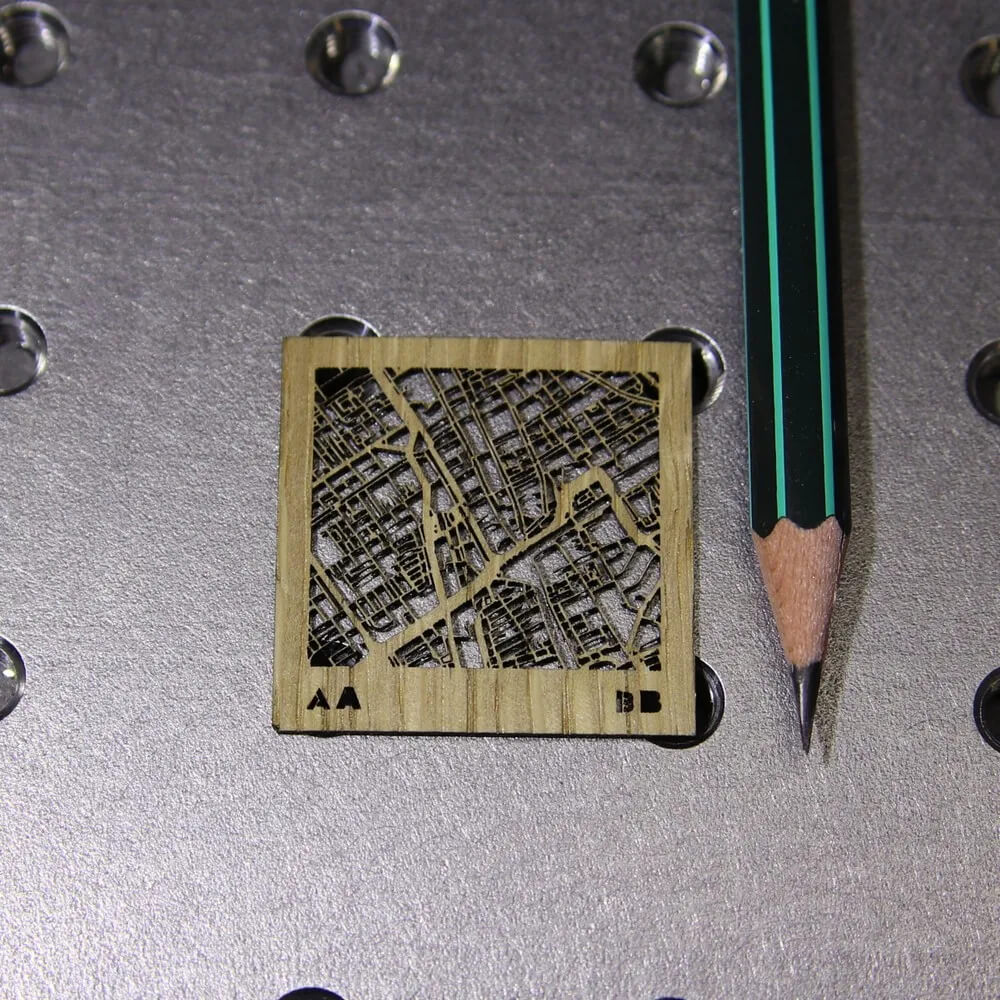

Detailed Engraving or cutting soft materials

This laser head can achieve < 50 µm precision for engraving on materials like wood, cardboard, paper, foam, rubber, acrylic or leather, to name a few.

This very small beam also allows to cut materials with thin even cut lines. Here are a few cutting capability examples:

- 10mm soft wood in 5 passes at 300 mm/min*

- 20mm poly foam in 4 passes at 780 mm/min*

- 2mm rubber in 1 pass at 1000 mm/min

- 1.8mm microsurfaced impact acrylic in 10 passes at 900 mm/min*

*using the high-pressure air nozzle assist

Ultra-HD Engraving

Up to 500 DPI engraving capacity on materials like ceramic tiles, with significantly faster results than other laser heads without anamorphic optics.

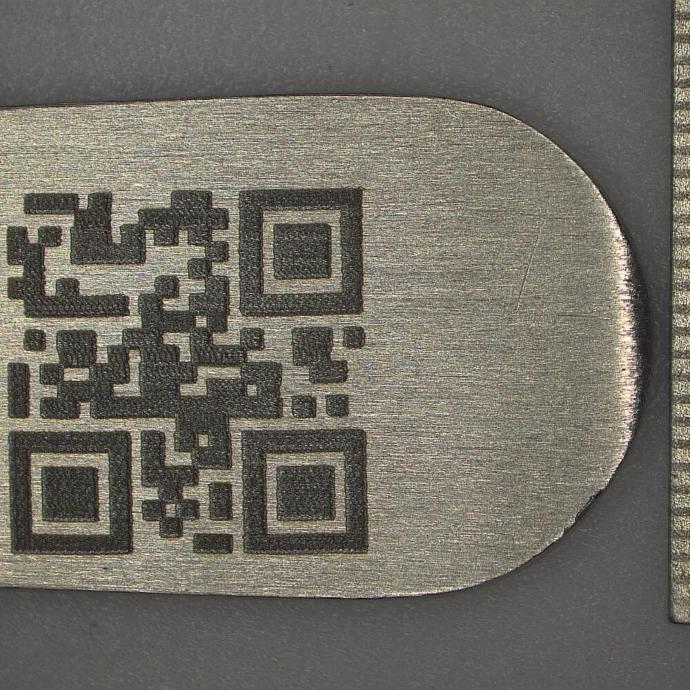

Accurate Metal Engraving

The microscopic beam spot allows to make precise and small engravings in a wide variety of hard materials, including stainless steel or aluminium.