Ce guide te permettra de programmer des usinages plus grand que ta machine en utilisant la technique dites du "Tiling". Nous abordons à la fois les parties CAD et CAM sur Autodesk Fusion ainsi que l'usinage.

Xavier Klein

CNC Training

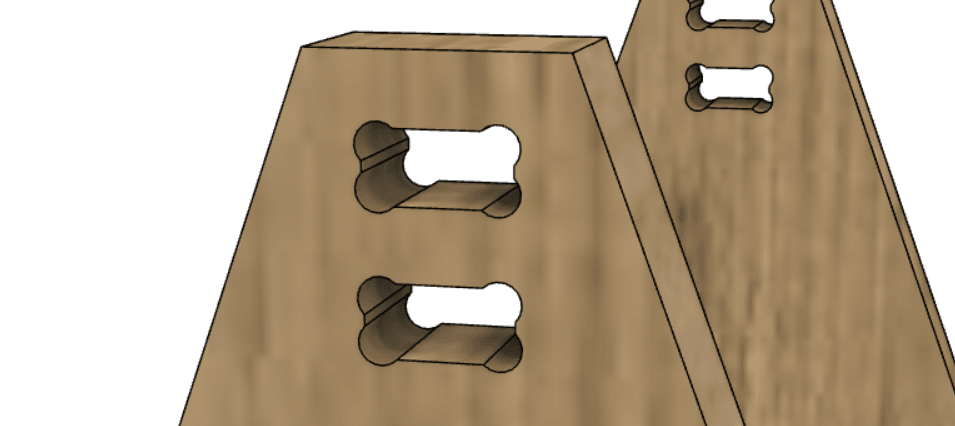

Chaque fois que tu veux assembler deux pièces à l'aide de tenons et mortaises, tu rencontres un problème : puisque tu coupes quelque chose à l'aide d'un outil rotatif, les coins internes seront arrondis ; l'outil ne peut pas couper des angles de 90°.

Il nous faut une solution, et elle s'appelle "Dogbones".

Voici comment les dessiner, et où trouver des add-ons qui les créent automatiquement pour tes projets complexes.

Prenons un exemple simple :

Nous avons ce modèle 3D et nous voulons le fraiser pour pouvoir y insérer une autre pièce.

Mais voici à quoi ressemblera réellement la pièce usinée : ses coins seront arrondis car la fraise est ronde.

Et il sera impossible d'insérer une autre pièce à l'intérieur parce qu'il y aura des interférences :

Dans la menuiserie traditionnelle, on élimine généralement ces coins arrondis à l'aide d'un ciseau à bois pour obtenir un angle droit parfait.

Mais dans le monde du fraisage CNC, où l'on cherche à automatiser les choses autant que possible, il existe un moyen d'éviter ce problème et de permettre à la deuxième pièce de s'insérer dans la première.

La solution, ce sont les "Dogbones" (appelés comme ça à cause de leur forme d'os pour chien) : en changeant la forme des angles intérieurs, ils ajoutent de l'espace pour que la fraise puisse passer et éviter les coins arrondis.

La solution la plus courante consiste à intégrer un congé en forme de cercle du diamètre de ton outil à chaque angle intérieur. Cela permet à l'autre pièce de s'y insérer.

Cependant, tu veux que ce cercle soit le moins visible possible, et la technique optimale pour y parvenir consiste à le décaler de la moitié du diamètre de la fraise à un angle de 45° (ou 135°).

C'est la solution qui permet d'éviter les angles arrondis en retirant le moins de matière possible, et donc la plus discrète. Note que plus l'outil utilisé est petit, plus le dogbone peut être petit.

Il existe une autre façon de créer des "dogbones" qui donne un résultat esthétique différent : en les plaçant sur un des côtés plutôt que sur l'angle.

Il suffit de placer un demi-cercle du diamètre de ton outil sur le côté de ta forme, tangent à l'autre côté de l'angle, et l'outil parviendra à dégager un angle de 90° pour permettre l'assemblage d'une deuxième pièce.

C'est une solution moins discrète mais qui peut avoir son charme propre.

Note que ces dogbones peuvent également être placés sur le petit côté de la poche, ce qui ajoute encore une autre possibilité esthétique.

Pour celles et ceux d'entre vous qui travaillent dans Fusion 360, il existe des compléments super pratiques qu'on te conseille de télécharger, qui créent des dogbones automatiquement !

C'est une extension complément gratuite que tu peux télécharger ici.

Vérifie la dernière version, télécharge le fichier zip dans les "assets" et suis ce guide pour l'installer.

Elle a des fonctionnalités basiques mais fonctionnera parfaitement pour les débutant·e·s ou les projets peu complexes.

Elle ajoute une nouvelle fonction dans Fusion qui fonctionne comme cela :

Crée ton dessin avec des bords réguliers et sans penser aux dogbones.

Dans l'onglet design, clique sur l'icône dogbone.

Sélectionne les arêtes que tu souhaites transformer en dogbones et entre les paramètres en fonction de l'outil que tu vas utiliser, ainsi que le décalage radial que tu souhaites.

L'outil créera automatiquement des dogbones sur tous les coins que tu as spécifiés.

Si tu utilises beaucoup de dogbones dans tes designs, on te recommande cet add-in plus avancé : Nifty Dogbone.

Il n'est pas très cher et gérera parfaitement les dogbones sur n'importe quel design complexe avec une option pour les actualiser après un changement de design.

Consulte leur page web qui contient plein d'informations utiles et de détails sur les dogbones.

Mekanika est une entreprise belge basée à Bruxelles dont l'ambition est de rendre la production locale plus accessible grâce à une approche 100% open-source.

Nous concevons et produisons des machines de haute qualité pour le fraisage CNC et la sérigraphie, qui ont été reconnues pour leur fiabilité et leur facilité d'utilisation. Nos outils sont livrés en kits et entièrement documentés, permettant facilement de les adapter à des besoins spécifiques.

Visitez notre boutique pour en savoir plus, ou consultez notre ressources en ligne et tutoriels pour continuer à apprendre.

Ce guide te permettra de programmer des usinages plus grand que ta machine en utilisant la technique dites du "Tiling". Nous abordons à la fois les parties CAD et CAM sur Autodesk Fusion ainsi que l'usinage.

Xavier Klein

CNC Training

Planet CNC offre la possibilité de démarrer un G-Code à partir d'une ligne spécifique plutôt que depuis le début. Cette fonctionnalité peut s'avérer utile pour reprendre un travail interrompu pour diverses raisons, telles qu'une panne de programme/ordinateur, une coupure de courant ou un arrêt d'urgence.Planet CNC offre la possibilité de démarrer un G-Code à partir d'une ligne spécifique plutôt que depuis le début. Cette fonctionnalité peut s'avérer utile pour reprendre un travail interrompu pour diverses raisons, telles qu'une panne de programme/ordinateur, une coupure de courant ou un arrêt d'urgence.Planet CNC offre la possibilité de démarrer un G-Code à partir d'une ligne spécifique plutôt que depuis le début. Cette fonctionnalité peut s'avérer utile pour reprendre un travail interrompu pour diverses raisons, telles qu'une panne de programme/ordinateur, une coupure de courant ou un arrêt d'urgence.

Quentin Liard

Customer Support

Découvre comment maximiser les performances de ta table à vide en apprenant des conseils pratiques sur les stratégies de coupe, l'entretien du spoilerboard et bien d'autres choses encore.

Maxime Gravet

Product Engineering