This guide will enable you to program machining operations larger than your machine using the “Tiling” technique. We cover both the CAD and CAM aspects in Autodesk Fusion as well as machining.

Xavier Klein

CNC Training

FreeCAD is a fast-evolving open-source parametric 3D software supported by a community of more than 500 developers. It’s entirely free - but you can support the project here – and features a robust CAM section that will get you milling complex projects on your CNC with confidence.

If you’re hesitating between some software, you can compare different CAD/CAM software here to make your choice and if you’re new to FreeCAD, you can download precompiled stable releases for Windows, macOS and Linux here.

When writing this article, we first tried the macOS version, and it had numerous bugs that we were not able to overcome, we switched to the Windows version and everything went smooth.

In this tutorial, we’re going to go through the CAM section of FreeCAD in order to mill our usual clamp. By the end of this article, you should be familiar with FreeCAD CAM interface and basic functions, and how to use it with your Mekanika CNC Machine.

The interface of FreeCAD is pretty common to other 3D software, and features the following sections.

We’ll focus on the CAM workbench (called Path in FreeCAD), but if you want to go deeper in understanding the interface, you can find more resources on the FreeCAD Wiki.

In the context of this tutorial, we’ll import our clamp *.STEP file directly, without drawing it from scratch. You can find the file here.

If you whish to learn the basic concepts of CNC milling, we'd suggest you go through our tutorial series first before following this specific tutorial for FreeCAD.

Before going any further, make sure you update your Preferences in the General Tab with “Metric small parts & CNC”, in order to be able to use the standard mm/min for your operations.

If you come from another software, make sure the navigation preferences are aligned to what you’re used to, it will highly improve your experience of the visual interface.

To access the CAM interface of FreeCAD, you have to select the CAM workbench (formerly Path). When in the proper workbench, the panel toolbar of your environment should look like this:

First, we’re going to create a Job. It’s the default view that contains all the information of a specific CAM job, meaning you can program several operations in it, as well as the information on the tools you use and your feeds & speeds.

Let’s click on the first icon from the toolbar: Create Job. This will a new job in your combo view, as well as new information on the Tasks view.

We’ll start by adapting the stock parameter of our job in the Tasks tab :

Note that creating a job generates a copy image of your model under the Job Tab, which appears semitransparent. You can always toggle the visibility of your original model as well as the one of the stock or of your job model, but you'll have to set your operations on the model inside your job.

Last but not least, before going further, make sure you assign the right postprocessor to your job. In the case of Mekanika machines, you can select LinuxCNC.

Before going further, we need to create tool profiles that match what we have available for our machine. For this, click on the ToolBit Library Editor. If it’s the first time you set up the library, FreeCAD is going to ask you if you want to set up the folder.

Once created, you’ll arrive to a screen with existing end mills.

To add a new end mill, click on the Create Toolbit button, then select the type of shape for your end mill. After selecting the shape, FreeCAD will ask you to name your new tool before you can change its parameters. You can then double-click on the new tool and adapt its shape and attributes.

Back to our job, you can now click on Toolbit Dock to see your end mills appear next to the 3D environment.

Note that unlike some other CAM programs, FreeCAD doesn’t attach speeds & feeds to each tool in the library, they have to be added in our job.

An additional tip before setting up your first operations: we like a useful AddOn that helps you calculate your feeds and speeds. It’s available here with the installation procedure depending on your computer setup, and will be visible under Path Addons once installed and FreeCAD restarted.

You'll need basic knowledge of Feeds & Speeds to use this AddOn, to calculate the proper chipload, but it will allow you to store materials data and use them way faster.

Back to the Combo View, under your job you can now see a TC object (standing for Tool Controller) with the name of your mill and all its parameters, including feeds & speeds. If you didn't set them using the AddOn, you can modify the parameters and feeds & speeds of your Tool Controller for this job.

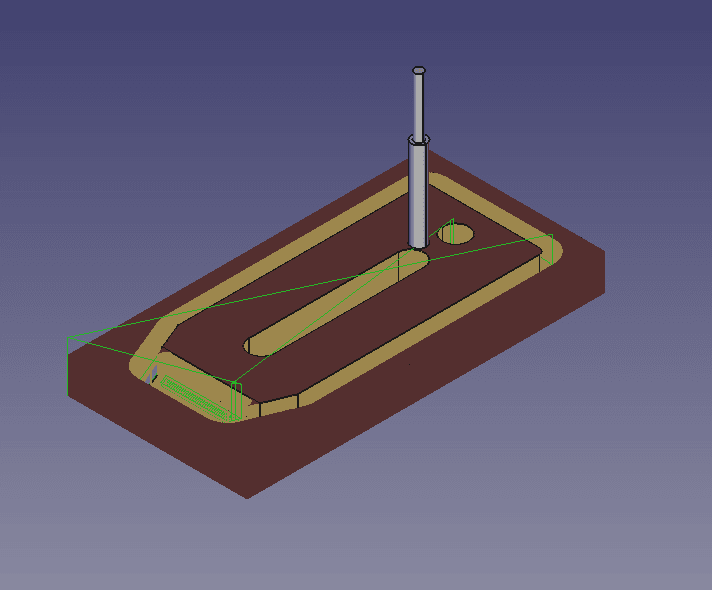

Now that we have our design, our tool and our feeds and speeds, we can start creating operations. For our clamp, we’re going to do three simple operations:

To create the pocket, we’ll use the Pocket Shape tool icon. A tab opens under the combo view with several interesting information :

Once you’re done, click on Ok and the tool path should appear on the 3D viewer screen. We’ll be able to simulate it, but let’s first do the same for the first contour operation called Profile in FreeCAD: select all face of the internal contour in the Base Geometry section, as well as your preferred parameters in the other sections.

In this case, we're going to have to select Internal in the operation section to mill the inside of the pocket.

Let's then do the same for the second contour.

Depending on the work holding methods you’ll use, it’s worth adding tabs to your tool path. In the Combo View you can click Path > Path Dressup >Tag. This should automatically create 4 tabs. You can then adjust their dimensions, geometries and placement in the Holding Tags section.

Once your operations are defined, a good practice is to simulate your full job before exporting anything to your machine. FreeCAD features a handy CAM Simulator Tool that allows you to check if everything works smoothly, and how your part should theoretically look after the milling.

After this final step, we're now ready to export our milling file. Before doing that, make sure the right post processor is selected in your Job, but check as well the export path of your G-Code files under Preferences.

You can now click on Post Process to generate your G-Code file and send it to your machine.

We have another tutorial on how to use your Mekanika machine for the first time when you generate your G-Code, that you can find it here and is adapted to any software you'd use with your machine.

Mekanika is a Belgian company based in Brussels whose ambition is to make local production more accessible thanks to a 100% open-source approach.

We design and produce high quality machines for CNC milling and screen printing, which have been recognized for their reliability and ease of use. Our tools are delivered as kits and fully documented, allowing to easily adapt them to specific needs.

Visit our shop to find out more, or check out our online resources and tutorials to continue learning.

This guide will enable you to program machining operations larger than your machine using the “Tiling” technique. We cover both the CAD and CAM aspects in Autodesk Fusion as well as machining.

Xavier Klein

CNC Training

Planet CNC offers the option of starting a G-code from a specific line instead of from the beginning. This can be useful for resuming a job that was stopped for various reasons, such as a program/computer crash, a power outage or an emergency stop.

Quentin Liard

Customer Support

Find out how to maximize the performance of your vacuum table by learning practical tips on cutting strategies, spoilerboard maintenance and many more.

Maxime Gravet

Product Engineering