Material

While carbon fibre composites are their final product, Vulcan Alpha's process begins with the machining of high-density foam supports. This specialised foam, carefully milled on their Mekanika Fab machine, forms the basis of their wings before being wrapped in carbon fibre materials.

Working environment

Vulcan Alpha operates from an environment equipped with a BigRep large-format 3D printer, SHINING 3D scanners and a Mekanika CNC milling machine. This configuration allows them to manage everything in-house, from initial 3D scanning and modelling through to prototyping and testing, ensuring total quality control at every stage of development.

Products

Vulcan Alpha creates distinctive carbon fiber wing solutions that tell a story of cutting-edge innovation. Their collection includes single and multi-element designs, with select models featuring an innovative drag reduction system (DRS). Their work spans both universal wing platforms adaptable across multiple vehicle types and bespoke designs tailored for specific makes and models.

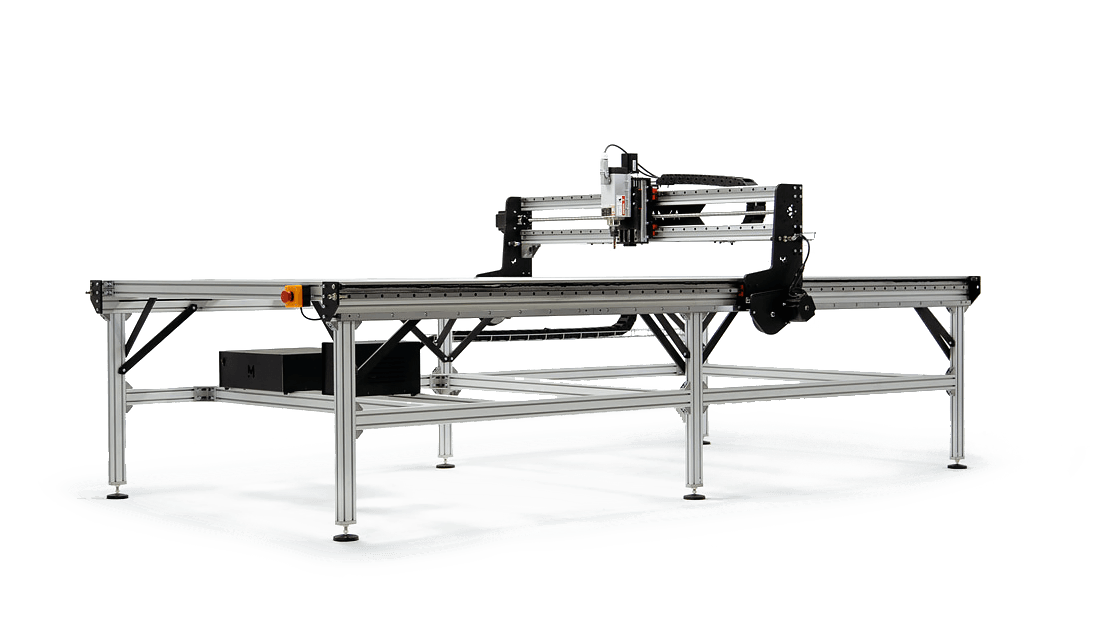

Machine setup

Central to Vulcan Alpha's production capabilities is their customized Mekanika Fab milling machine, which features advanced Z-axis capability for precision manufacturing. This upgraded configuration allows them to mill intricate wing profiles with greater depth and complexity, delivering the aerodynamic components essential for their specialized applications. The machine's superior capabilities ensure consistent quality while meeting the demanding requirements of motorsport vehicles.

Discover the Fab

The best craftsman's ally

The Fab is the largest in the Mekanika range. But even though it measures over three meters, its kit design means it can fit through any door and into any workshop! Read more about the features of this machine on the product page.