Pro

For Us, That's a Given

Five years warranty

- Our machines are designed to last. To support that statement, we're offering a 5-year warranty – the best warranty terms on the market.

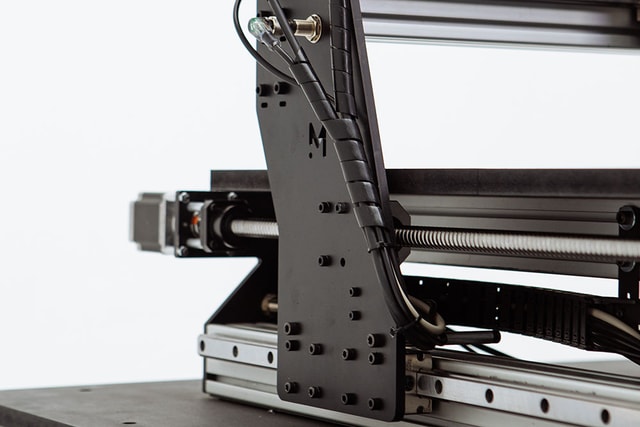

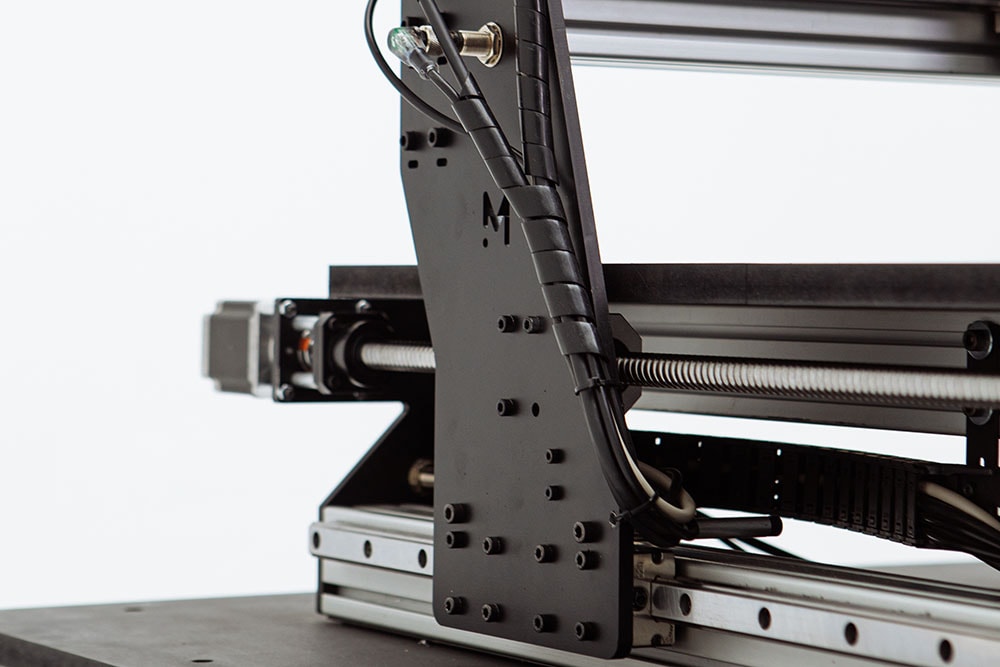

Open and modular design

- Our open-source designs make it easy for you to understand, modify and maintain your machine. No black boxes, no planned obsolescence – this tool is yours.

Easy Workflow

- Our animated assembly guides, intuitive interfaces and video tutorials on CNC machining will accompany you every step of the way, from assembling your machine to using it.

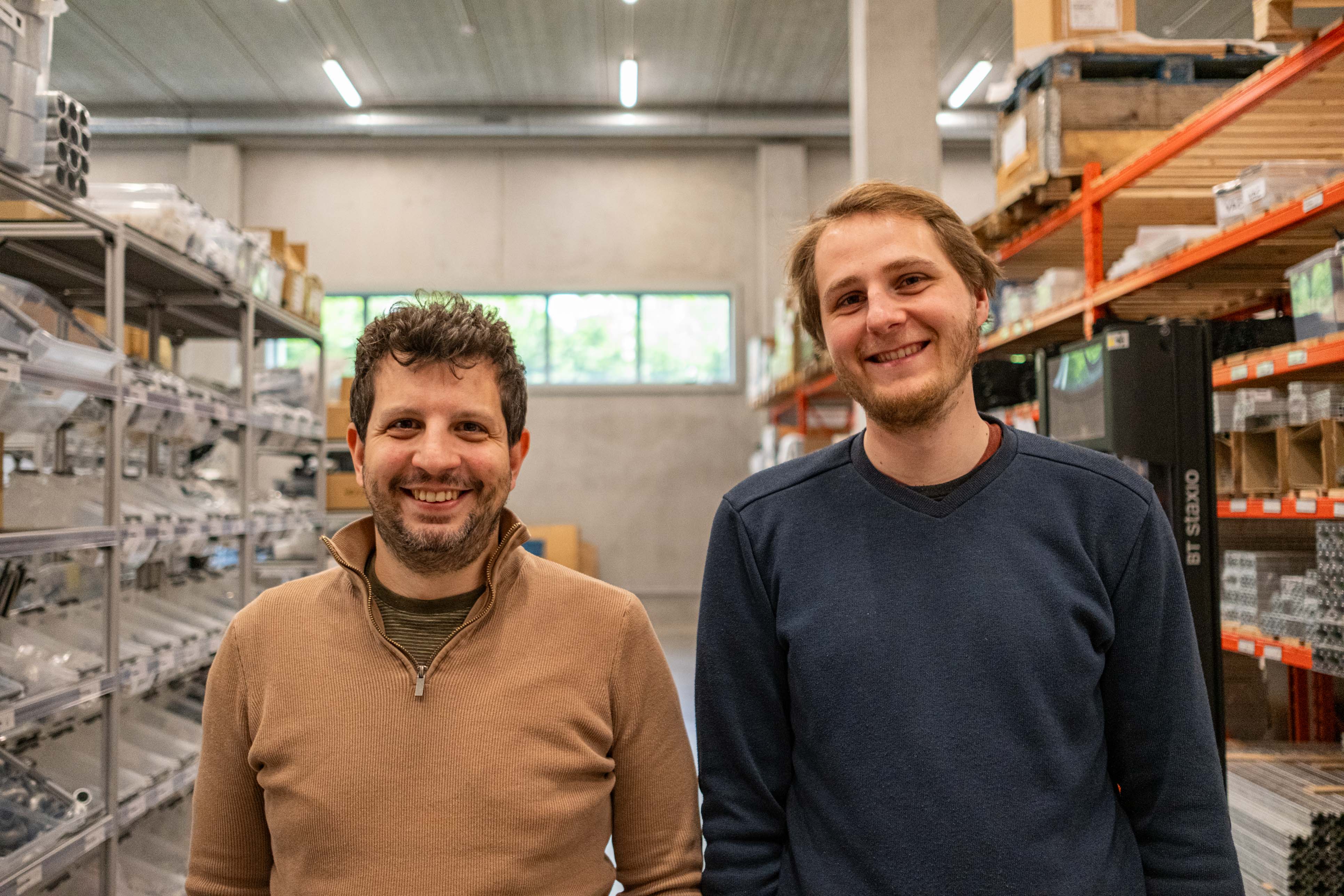

Belgian manufacturing and service

- Mekanika is based in Brussels, where we design and assemble our machines. We invest a great deal of effort in ensuring that all our customers feel listened to, and we strive to respond within 24 hours. We find solutions to all your problems.

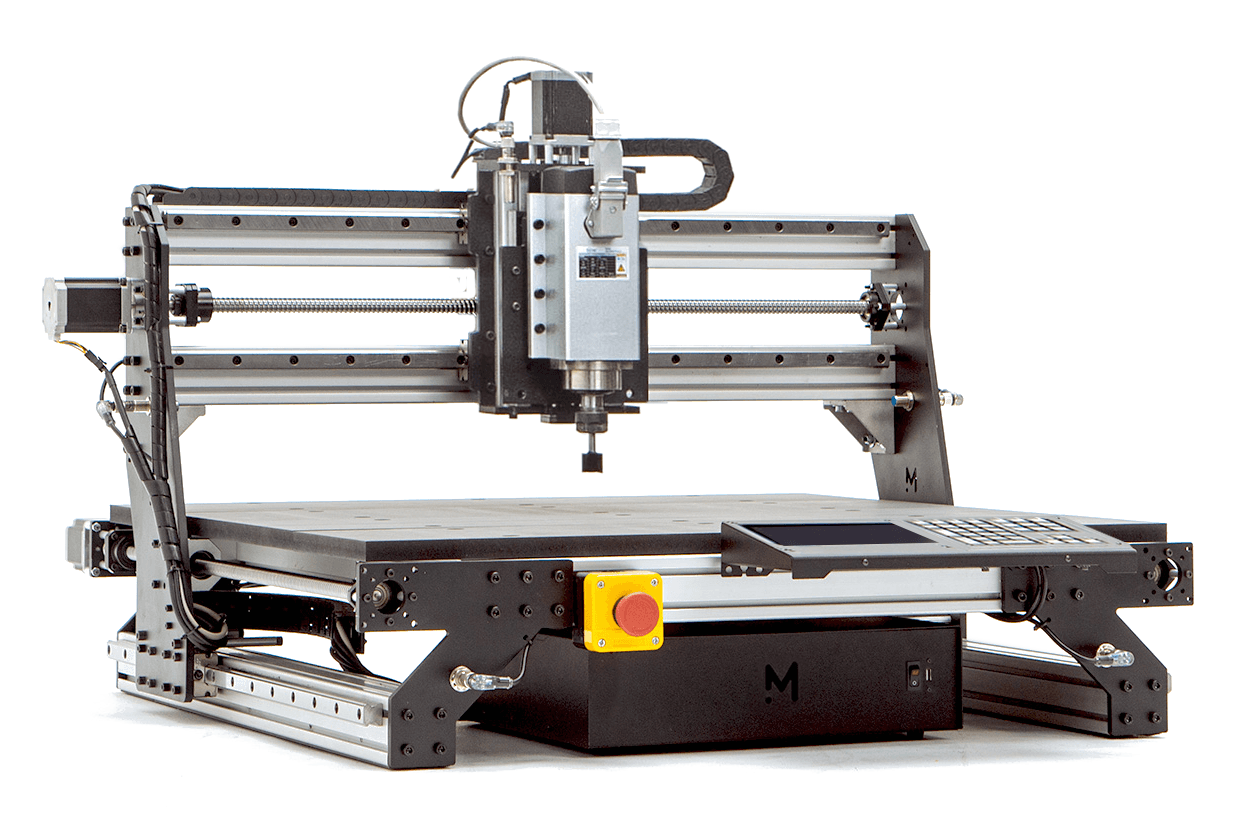

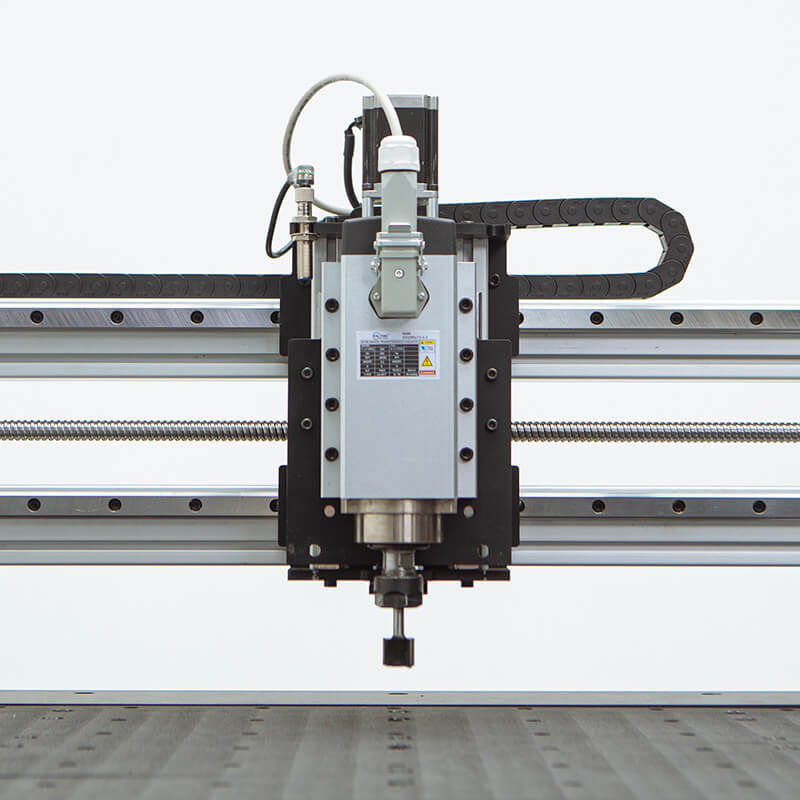

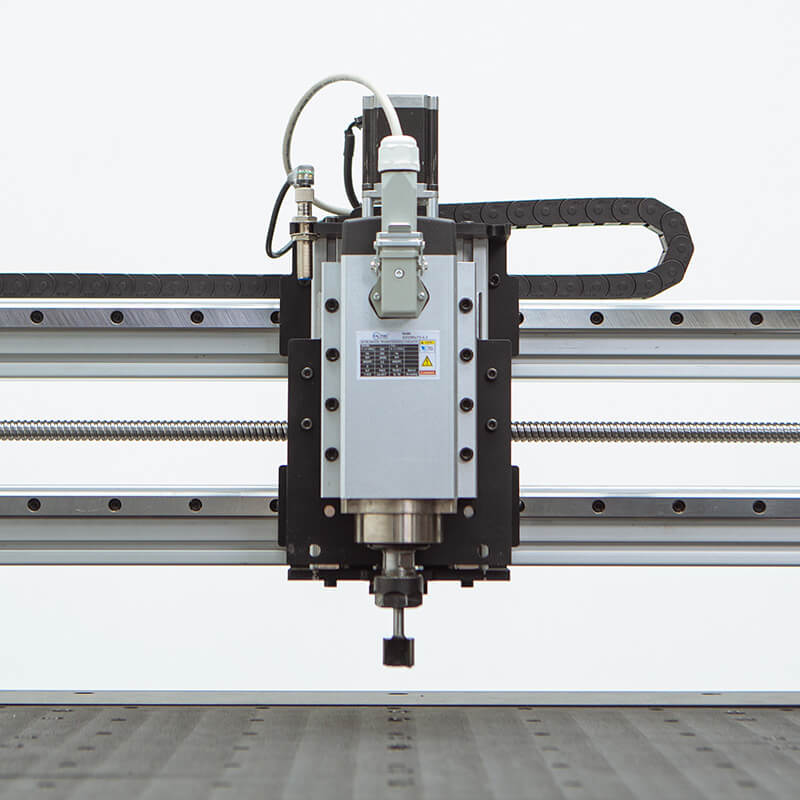

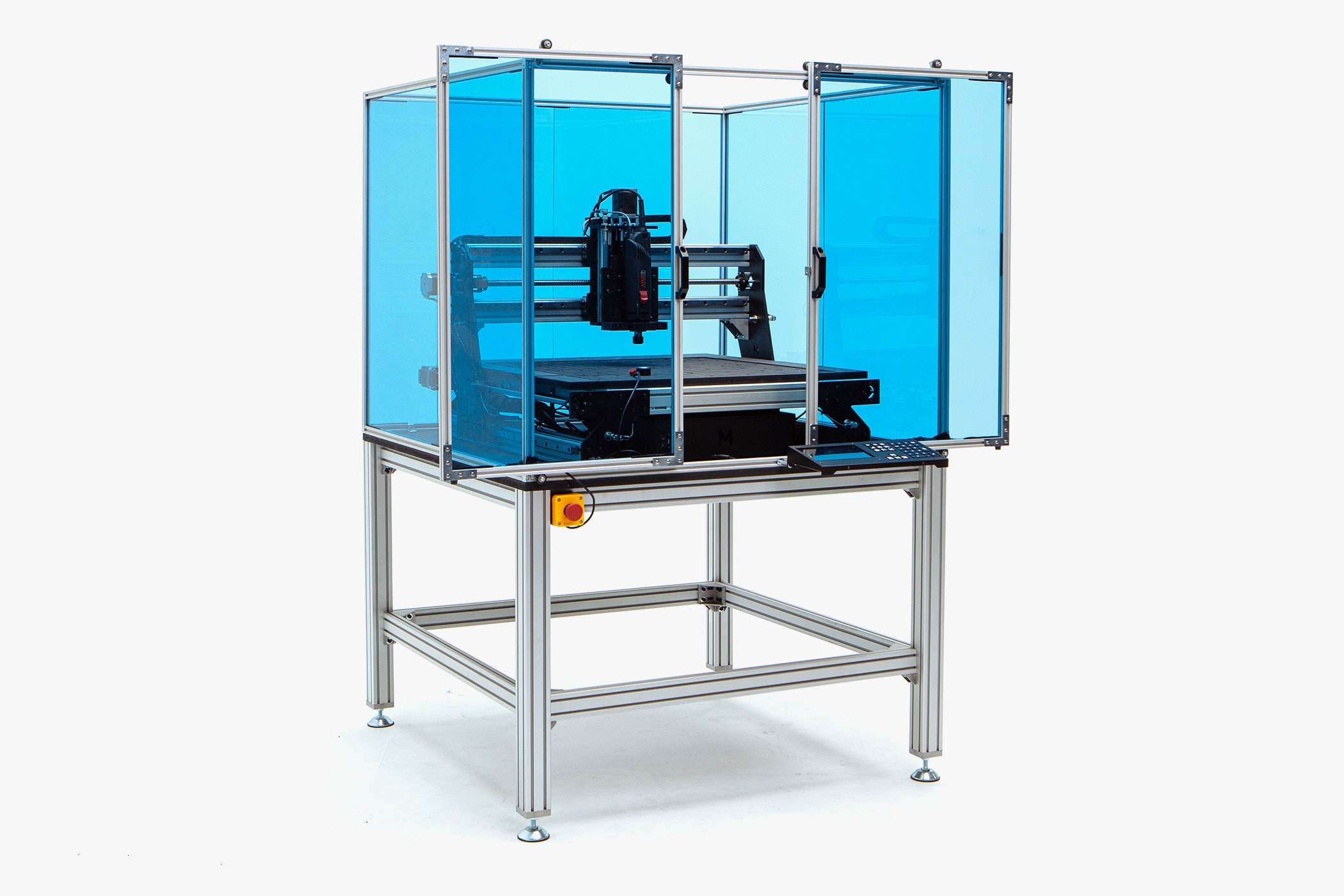

An All-Terrain Machine

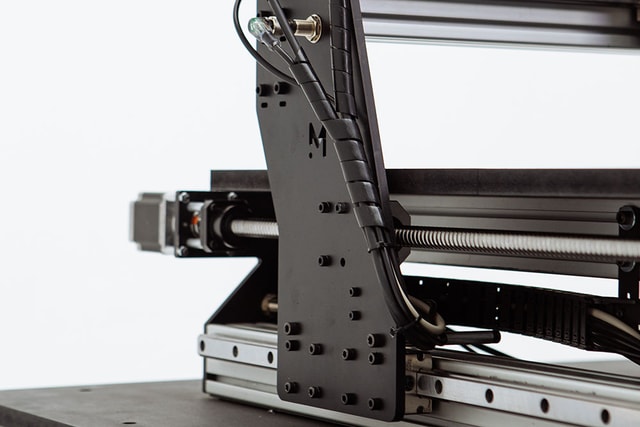

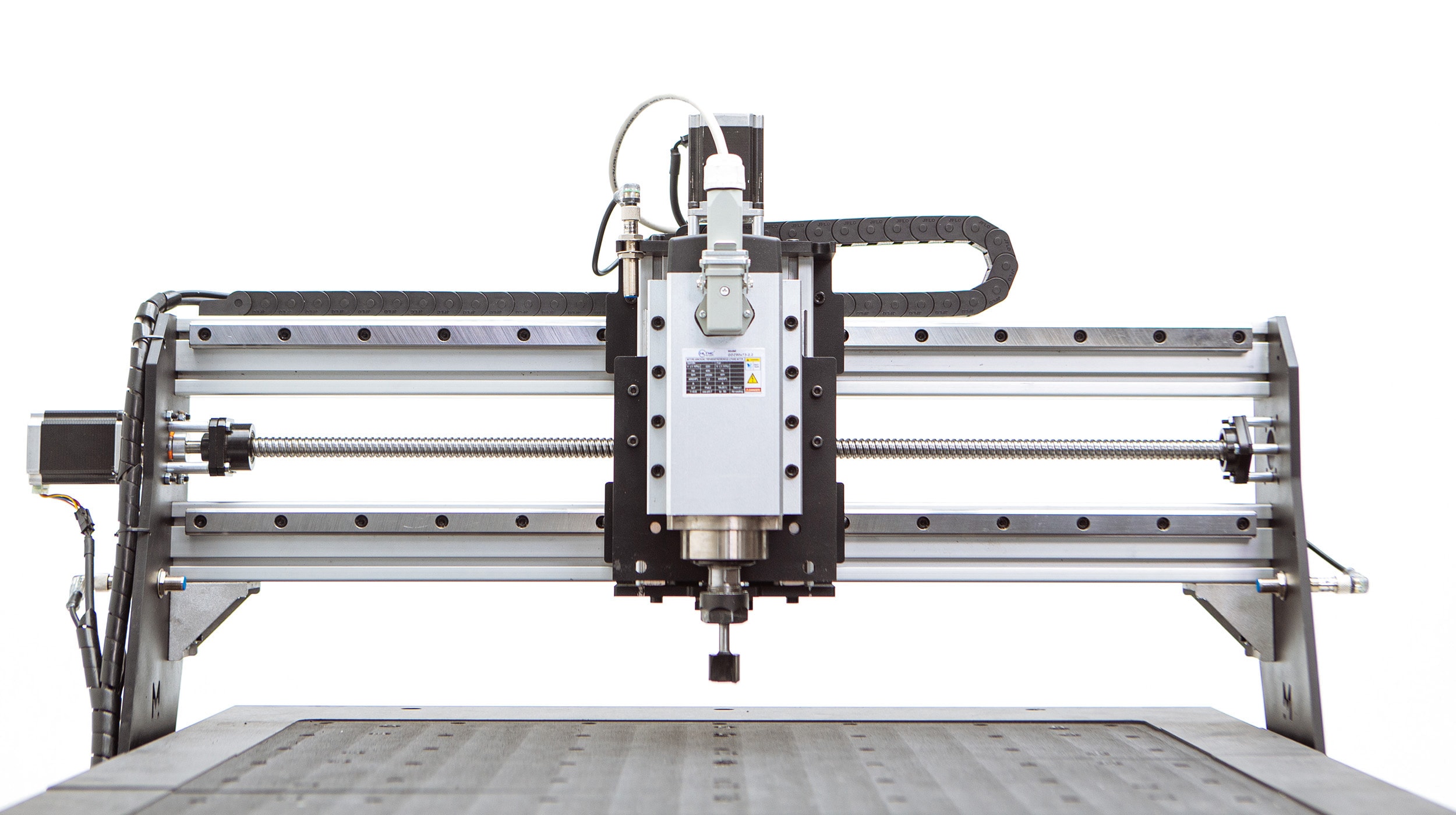

Steel & Aluminium

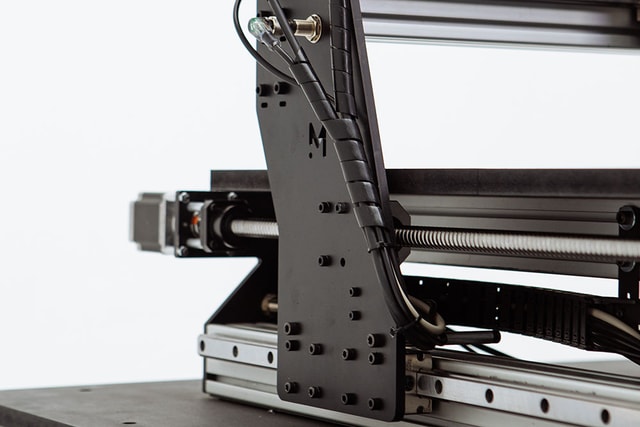

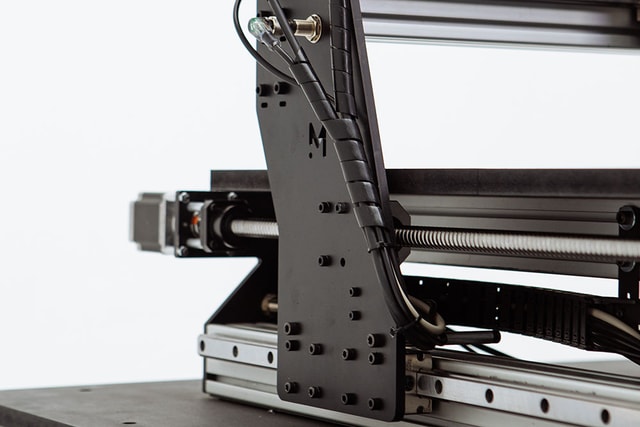

Stable and massive

- 8 mm thick steel plate

- Reinforced aluminum structure

- From 60 to 80 kg depending on size

- Reduced footprint

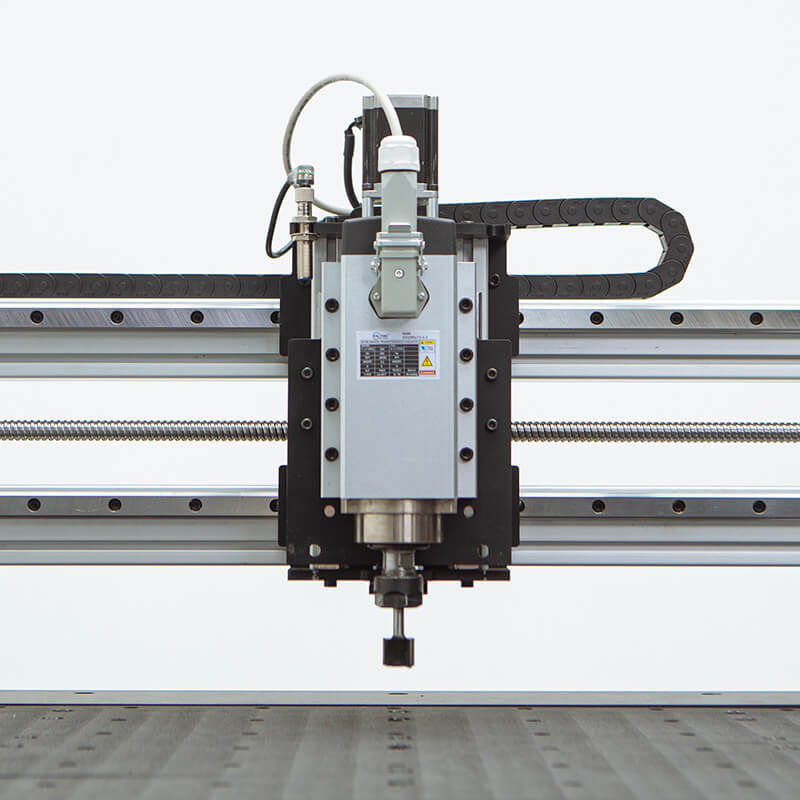

Discover Pro in Video

A good overview to understand the machine

William explains just about everything - from how to use the machine to the spindle powers available - and the various safety points. After that, you should have a much clearer picture!

Pimp Your Pro

A Full-Option Machine!

Adjust your pack according to your needs

The Pro is a versatile machine that adapts to many situations and materials. We have developed numerous accessories to suit your needs.

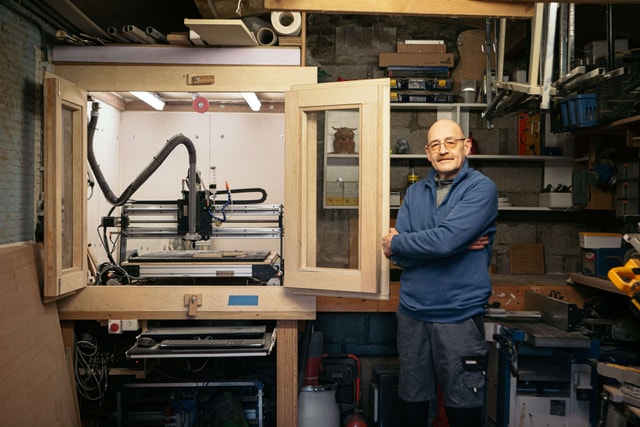

Delivered as a Kit

The design of Mekanika machines is based on an open and modular approach, known as the open-source principle. We always design our products with modularity and disassembly in mind: nothing is glued or welded, we use standard parts wherever possible, and all components can be easily replaced or repaired.

By assembling your machine, you gain valuable knowledge about how it works and how to maintain it. This will give you a machine that will last a lifetime.

Finance Your Investment

Mekanika Financing is our financing solution for professionals, in partnership with Grenke. It is a financing programme that allows you to purchase Mekanika machines with low fixed monthly payments. The minimum financing amount is €500 excluding VAT. Only eligible for France and Belgium at the moment.

- Minimum financing amount

- 500€

- Maximum leasing period in months

- 60

- This is the time we take to analyse your demand

- 48h

Your Best Ally

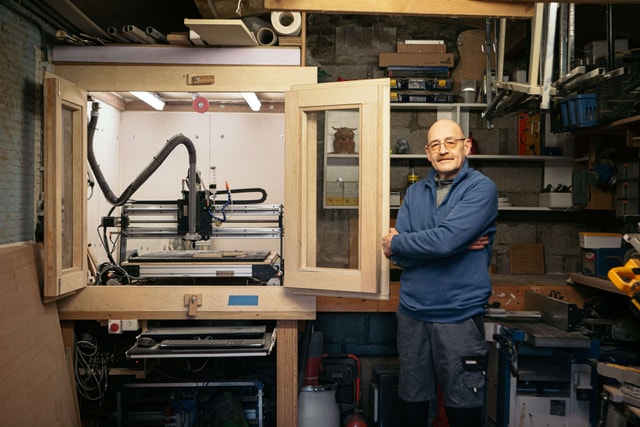

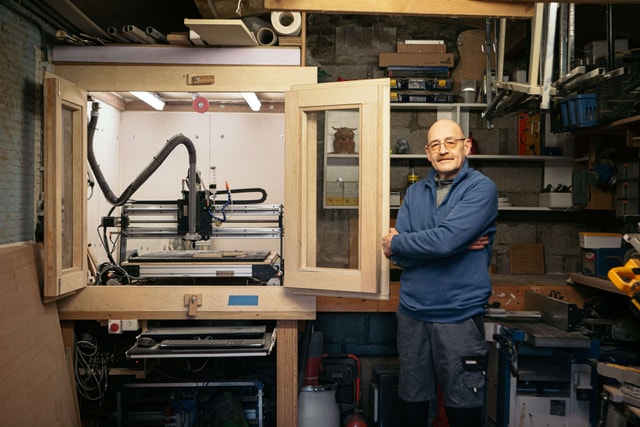

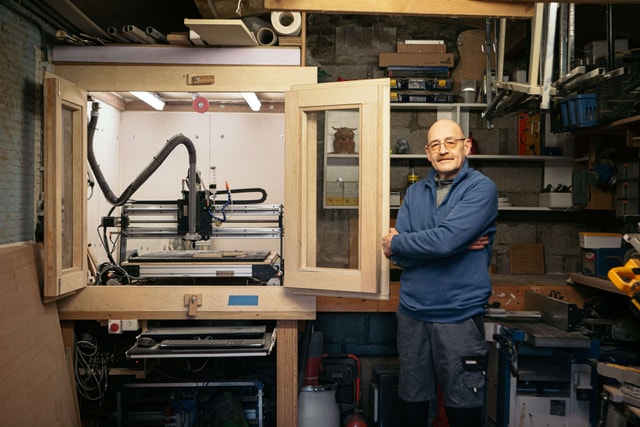

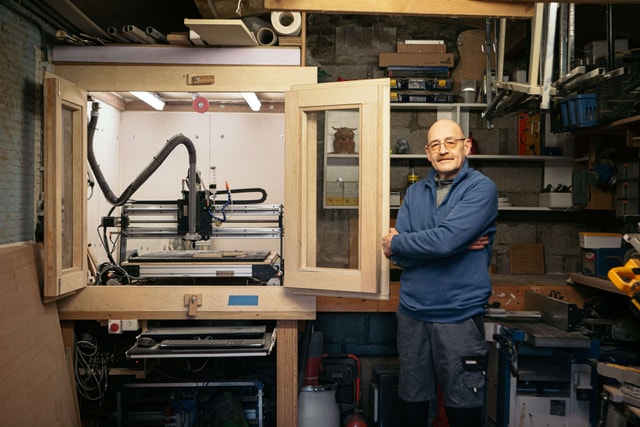

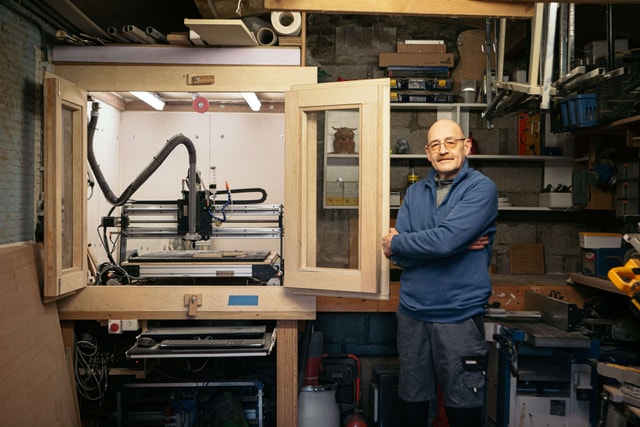

Pro in a Design Studio

Furniture made from waste from Duplex Studio

Our goal is to limit waste and surplus from industrial production by creating furniture and objects that give a second life to discarded materials.

More CNC Users

Check out our "User Stories" section to find out more about what others do with our machines!

Take the Time to Compare

We suggest you compare our two most efficient models, namely the Pro model and the Fab model.

| CHARACTERISTICS |  PRO |

FAB |

|---|---|---|

| Price | from 4.702€ VAT excl. | from 11.094€ VAT excl. |

| Assembly time | approx. 8h | approx. 20h |

| Working area | up to 1030x1030mm* | 1350x2750mm |

| Depth of cut | upt to 90mm** | up to 90mm** |

| Structure | 8mm steel/aluminum profiles | 10mm steel/aluminum profiles |

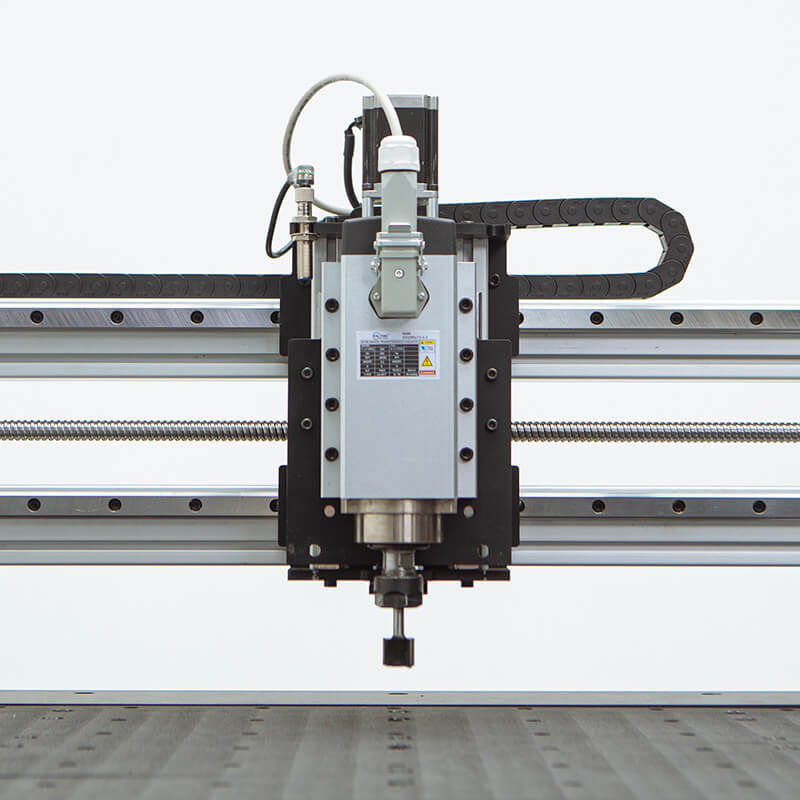

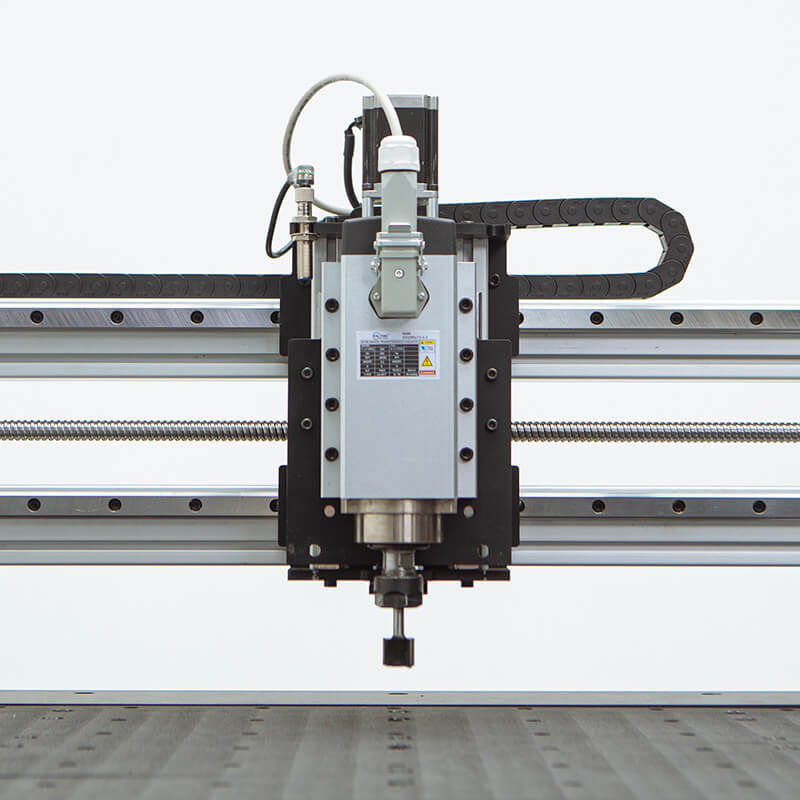

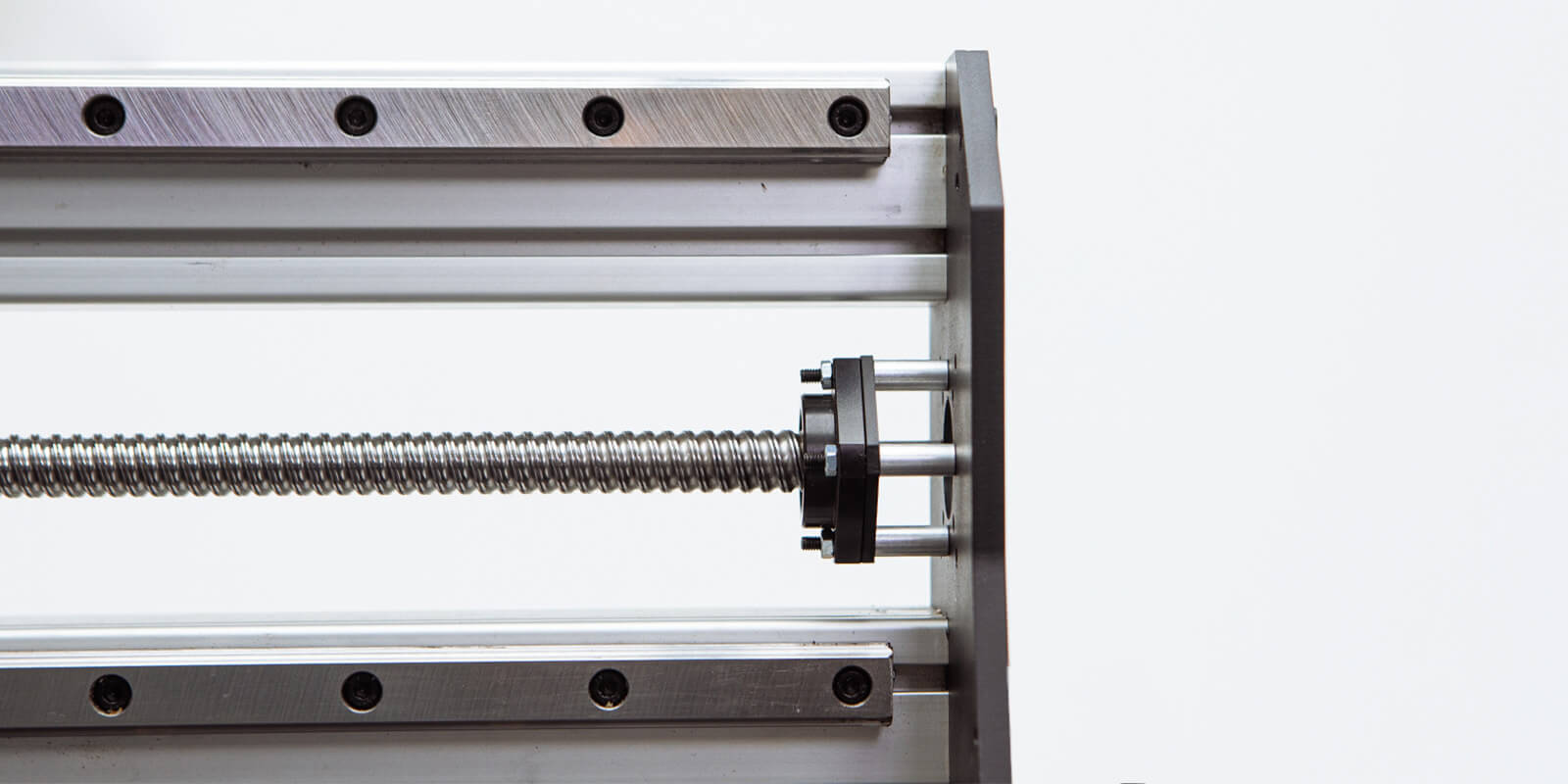

| Guiding system | Prismatic steel rails | Prismatic steel rails and racks |

| Drive system | 16mm ball screw | 16mm ball screw (XZ) and pinions (Y) |

| Positioning accuracy | 0,1mm | 0,1mm |

| Working accuracy | 0,1mm | 0,1mm to 0,2mm*** |

| Max. travel speed | 12.000mm/min | 20.000mm/min |

| Max. cutting speed | 7000mm/min**** | 7000mm/min**** |

* 3 sizes available: S=630x630mm / M=630x1030mm / L=1030x1030mm

** Without option = 50mm / “High-Z” option = 100mm

*** Vary according to the length of cut

**** Indicative values for reconstituted wood such as MDF

Full Tech & Specs

If you would like to know more about all the technical and electronic details of the Pro or the Fab, follow these links.

Still Have Questions?

Do you have questions about how to use the software or how to machine a specific part? Are you wondering if you have the necessary skills or if we offer support? Are you hesitating between two models or want a demo?

Contact us using our form. We will respond to you within 48 hours without exception.