This guide will enable you to program machining operations larger than your machine using the “Tiling” technique. We cover both the CAD and CAM aspects in Autodesk Fusion as well as machining.

Xavier Klein

CNC Training

With over 25 years of existence, SketchUp is a well-established 3D modeling tool, particularly in the architectural world. The software is quite ergonomic, offering a wide range of options for those wishing to create spatial visualizations from 2D plans with just a few clicks.

But the software is not limited to architecture: it can also easily be used to design parts that can be machined using a CNC machine, as we shall see.

At the time of writing, SketchUp offers several types of pricing plan, but not all of them allow you to manipulate all files.

For example, if you wish to import a DXF file into SketchUp, you will need to pay at least a hundred euros per year for a "Go" version capable of handling it.

A free version of the software is also available, but its options are limited, and it offers only limited compatibility with certain file types.

For one-off projects, more complete versions of SketchUp are also available with a free 7-day trial.

Note: For the time being, a free version of the Windows application SketchUp Make 2017 is still available for download at certain locations on the web, providing a dated but nevertheless complete version of the software without having to put your hand directly in the wallet. However this version doesn't handle certain file formats (like DXF standard, for instance).

Have you just finished lovingly polishing your design in SketchUp, and now want to materialize the fruit of your labor with your CNC?

I've got good news and bad news for you:

The bad news: SketchUp isn't really designed for 3D machining operations.

The good news: there are several technical solutions to overcome SketchUp's CAM (computer-aided manufacturing) shortcomings.

Several options are available:

It's totally possible to start from a two-dimensional design and parameterize a cutting operation directly on your machine (Mekanika) equipped with PlanetCNC.

Certain projects requiring assembly can thus be carried out by cutting several flat parts, which can then be assembled face by face to obtain a three-dimensional model.

The possibilities offered by this solution are interesting when it comes to designing cabinets, closets or other storage spaces, and some creative applications take the concept quite far.

However, they are much more limited if you want to tackle 2.5D operations from a real block of material.

A number of extensions can currently be added to SketchUp to compensate for the absence of native machining functions.

Here is a non-exhaustive list:

Autodesk Fusion 360 , FreeCAD , Autocarve: there's no shortage of specialized CAM options once you've drawn your part in SketchUp, the downside being that some tools may prove less intiuitive or more expensive.

SketchUp is definitely not made for CAM operations and it shows. After having tested a serie of options, your best shot to use it this way would be to export your model in another, specialized CAM software.

In our case, we chose Autodesk Fusion 360 to go forward and generate our G-Code as the free version allows to handle 3D files format like .STL or .OBJ.

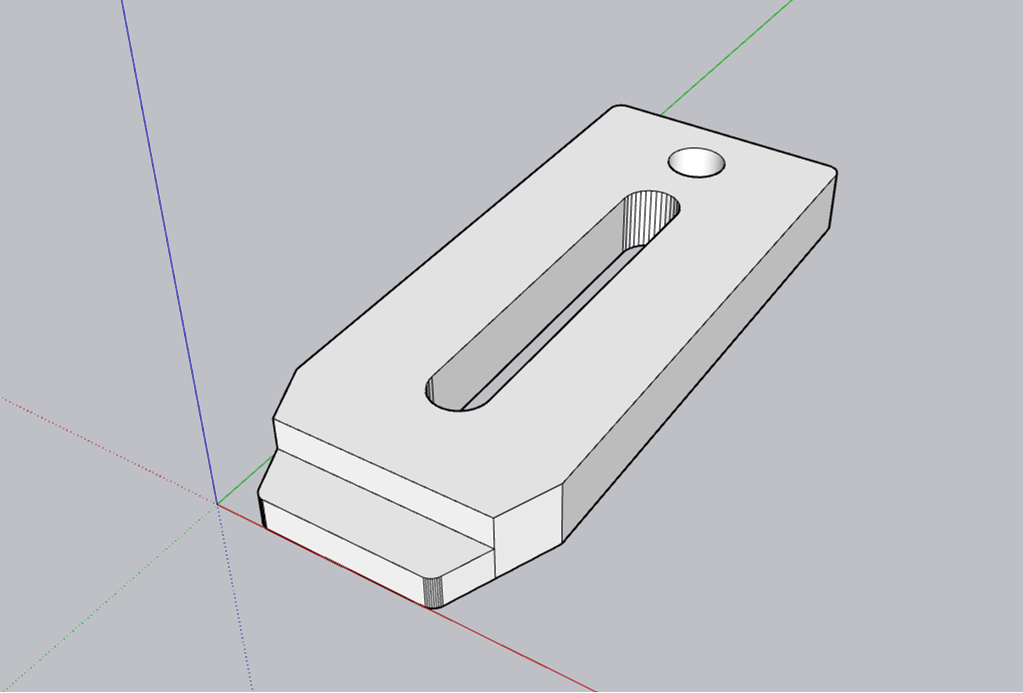

Once you've opened SketchUp, start by importing the clamp model we usually use in our exercises (downloadable here), by clicking on File > Import.

Your clamp design will appear on the screen, if not, try to move your view around using the hand option (shortcut "h") and/or rotating completely the view using the orbit option (shortcut "o") to find your design.

Now you'll need to give your clamp a surface and a volume.

Start by clicking on one of the lines of your design to select it, then right-click to select "modify component".

Then draw a line (shortcut = "l") through the design to give the object a surface.

Immediately delete the line (by selecting it and pressing the "delete" key).

Now select your entire "clamp" and right-click on "Create group".

Right-click again to split the group you've just created so that each surface can be manipulated independently and delete both hollow parts of your design by selecting them and pressing the "delete key"

You can now extrude your design (shortcut = "p") to the required dimensions by selecting the surfaces one by one and then changing their respective thickness (in our case 1cm for the main body and 0,5 cm for the tip.

Note that to define the height of your piece with precision, you need to "pull" it with your mouse and then type the height you need using the measurement unit your SketchUp version uses.

That's it, you are now done with the CAD part of the operation.

With your design now in 3D, it's time to export it to Autodesk Fusion 360 so that we can move to the CAM part of the operation.

Go to File>Export>3D Model and chose the format you want.

The free version of Autodesk Fusion 360 (personal use) only allows to use a limited types of files with the .STL and .OBJ standards common to both SketchUp and Autodesk Fusion 360.

In our case, we opted for the stereolithography (.STL) format as it was the least demanding in terms of amount of subsequent manipulations.

You can now open Autodesk Fusion 360 and open your file.

Click on "Open from my computer" and browse your drive to select the STL file you just created.

Your design should now be showing on the screen.

To convert it into a physical object, select your whole object and then go to the "Mesh" menu and select Modify>Convert Mesh and click on "OK".

Your object is now solid, but does it have the right size?

In our case, the export from Sketch Up to Autodesk Fusion 360 shrank it by a 10 factor. To remedy this issue, you can

Go to Solid>Modify>Scale

Select your whole object and scale it back to the size you want

That's it!

Now that your piece is ready to be made in Autodesk Fusion 360, you can simply follow the steps explained by Martin in his video tutorial in order to generate your precious G-Code.

Mekanika is a Belgian company based in Brussels whose ambition is to make local production more accessible thanks to a 100% open-source approach.

We design and produce high quality machines for CNC milling and screen printing, which have been recognized for their reliability and ease of use. Our tools are delivered as kits and fully documented, allowing to easily adapt them to specific needs.

Visit our shop to find out more, or check out our online resources and tutorials to continue learning.

This guide will enable you to program machining operations larger than your machine using the “Tiling” technique. We cover both the CAD and CAM aspects in Autodesk Fusion as well as machining.

Xavier Klein

CNC Training

Planet CNC offers the option of starting a G-code from a specific line instead of from the beginning. This can be useful for resuming a job that was stopped for various reasons, such as a program/computer crash, a power outage or an emergency stop.

Quentin Liard

Customer Support

Find out how to maximize the performance of your vacuum table by learning practical tips on cutting strategies, spoilerboard maintenance and many more.

Maxime Gravet

Product Engineering