This guide will enable you to program machining operations larger than your machine using the “Tiling” technique. We cover both the CAD and CAM aspects in Autodesk Fusion as well as machining.

Xavier Klein

CNC Training

CorelDRAW is a professional graphic design suite, originally designed as a vector graphic software.

It is not purposedly designed for CNC milling and does not include the usual CAD/CAM logic, but you can use it to export vector files that you will either be able to use in Fusion 360, or to import directly in your Mekanika CNC machine.

In this tutorial, however, we’re going to go through CorelDRAW and a new plugin called CamDRAW - available only for Windows as from 2018 - in order to mill our usual clamp from start to finish without leaving the CorelDRAW environment.

This article is intended for existing users of CorelDRAW who should, by the end of this article, be familiar with CamDRAW interface and main functions, and how to use it with your Mekanika CNC Machine. You’ll also find a section with advice on how to adapt your vectors drawings for CNC milling.

If you’re hesitating between some software, you can compare different CAD/CAM softwares in our article to make your choice.

If you’re new to CorelDRAW and CamDRAW, you can subscribe to their services following those links.

CamDRAW is a plug-in integrating into the Corel interface to allow it to generate G-Code. The first step is to download it here and to install it. Make sure you’re affecting it to the right version of CorelDRAW.

After restarting your computer, you should find the plugin directly available in your CorelDRAW interface under Tools > CamDraw. It will launch a side panel in your CorelDRAW interface.

The first time you start the software, you'll be asked to select a post-processor, which should correspond to your machine. In our case and since version 4.5 of CamDRAW, you have the choice between 2 Mekanika post-processors:

One without smoothing (called "Mekanika CNC Routers.pp"), the other with smoothing set at 0.1mm (indicated "Smoothing" in its name). They have a very little difference, but the smoothing will make the angle movements a bit softer for the machine.

We usually suggest to start by encoding all the end mills you want to use for your job before starting to program operations. In the case of this simple clamp, we’re going to use a 6 mm downcut end mill.

To access the Tool Library, go to the side panel under Toolpath > Open Tool List.

The menu is pretty straightforward: you can add a new tool, name it, and define its parameters. Note that you will already have to append feeds and speeds values to your tools, that will be reused by the operations, but you can always modify them on the operation level.

Unlike other CAM software, you’ll have to calculate your Feeds & Speeds by yourself, and there’s no available plugin to simplify this task. You can refer to our dedicated article to know more about how to do this.

The different tool parameters you’ll need are the following:

Now that everything is set up, we can import our vector drawing (if not done yet).

The .*DXF file is available here.

As a reference, the 3D view of the clamp we’re going to mill is as follows:

Our part is 100x40mm. In the first section of the side panel, we’re going to define the coordinate convention:

You can do as you wish, but always remember your choice to make sure the position of your operations are aligned with your stock. In CamDRAW, this is always done in 2D, under the XY axis. You’ll be able to define the origin of your Z-Axis further.

We can now start to define our different operations. Note that you cannot switch the order of the operations after you programmed them, so define your order from the beginning.

For example, you’ll always want to mill your pockets before the contour of your clamp to make sure it is well attached when doing the pocket operations.

Our milling job consist of 4 elements:

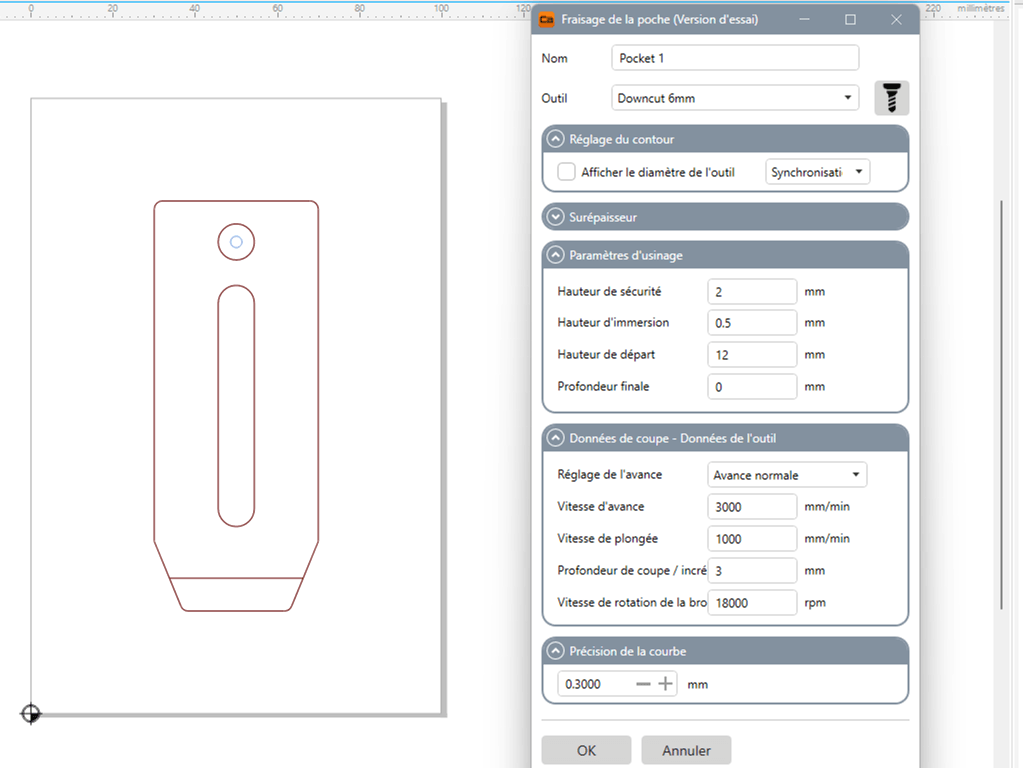

Let’s start by making the Pocket 1. For this, select the round on the drawing and click on Machining Type. Here, we’re going to use Pocket.

A new menu opens with different sections. You can leave most parameters standard for simple operations, but you have to check the following ones:

The second internal pocket will have to be done with a Contour operation.

Select the outline of the long pocket, and select Contour in Machining Type. Here again, we’re going to select our end mill, and it is especially important to select Internal when choosing if the tool path is to be centered or outside the vector outline. The rest of the parameters are similar to our first pocket.

After making those first two operations, you can visualize your tool path by clicking on G1G2 to check if everything looks similar to what you want.

The third pocket in the front will also be done with the Contour operation, by selecting External this time. We’re also going to put the final depth of our operation to 6mm, to create a pocket instead of a milling operation going through.

Last but not least, we’re going to make a Contour operation to outline the clamp in itself, with similar parameters as the previous operations.

Note that there are no tabs option in CamDRAW, forcing you to select a clamping system that is safe and will prevent your part from flying away in the room. Our experience is that CorelDRAW + CamDRAW is best suited for big parts attached through a proper vacuum system, and for engraving or sign making.

Once done, you can check the visual tool path to make sure everything looks good and export your G-Code by clicking on this button.

You’re now ready to mill your clamp! We have a tutorial on how to use your Mekanika machine for the first time when you generate your G-Code.

There are a few things to pay attention to when drawing for CNC milling:

After a few trial and error, you’ll have the experience to project yourself into the milling while drawing, making the process a breeze!

Mekanika is a Belgian company based in Brussels whose ambition is to make local production more accessible thanks to a 100% open-source approach.

We design and produce high quality machines for CNC milling and screen printing, which have been recognized for their reliability and ease of use. Our tools are delivered as kits and fully documented, allowing to easily adapt them to specific needs.

Visit our shop to find out more, or check out our online resources and tutorials to continue learning.

This guide will enable you to program machining operations larger than your machine using the “Tiling” technique. We cover both the CAD and CAM aspects in Autodesk Fusion as well as machining.

Xavier Klein

CNC Training

Planet CNC offers the option of starting a G-code from a specific line instead of from the beginning. This can be useful for resuming a job that was stopped for various reasons, such as a program/computer crash, a power outage or an emergency stop.

Quentin Liard

Customer Support

Find out how to maximize the performance of your vacuum table by learning practical tips on cutting strategies, spoilerboard maintenance and many more.

Maxime Gravet

Product Engineering