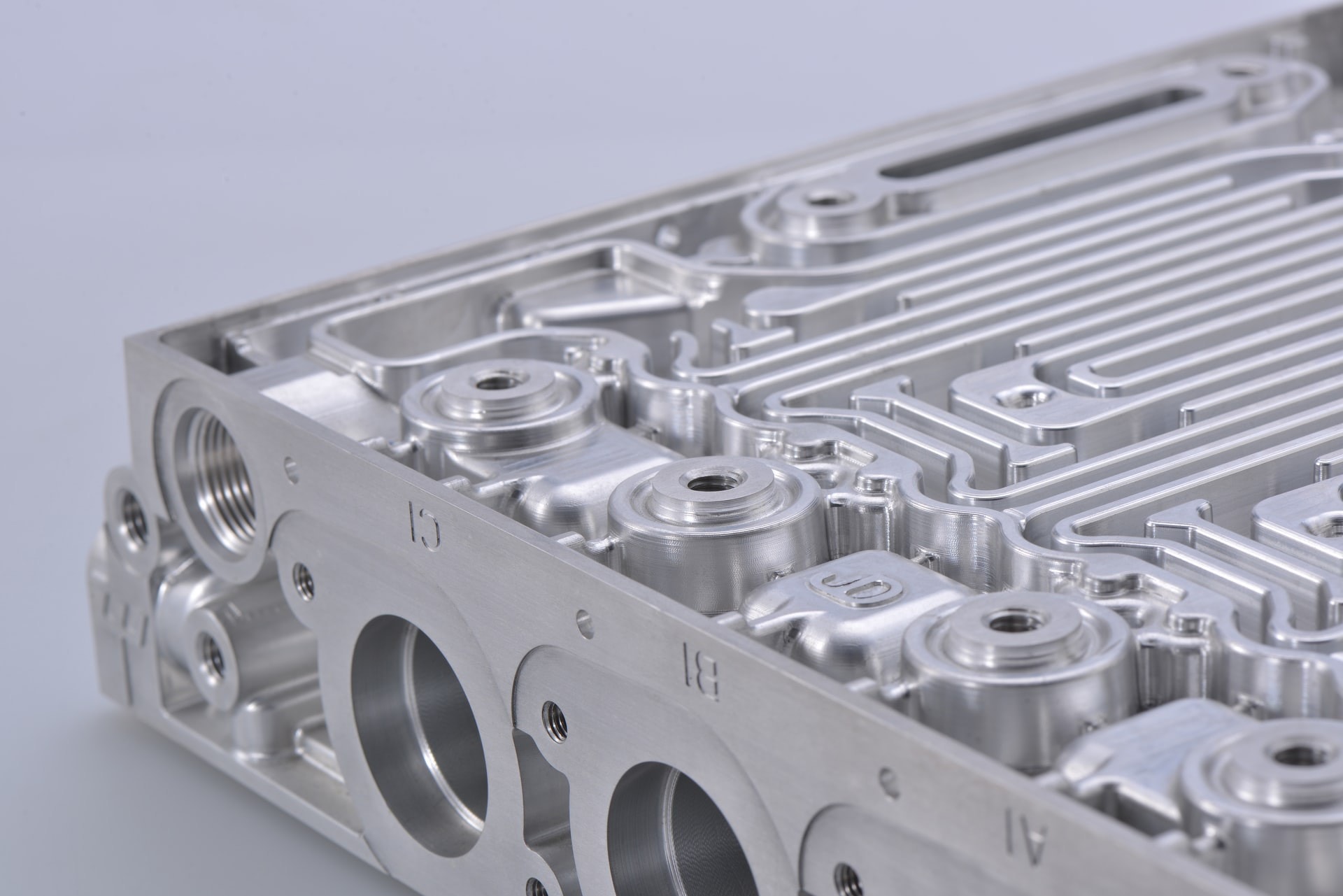

Are you learning CNC milling? Here are some tips and tricks to improve and optimize your CNC workflow, from work preparation to end mill selection.

Roldan Descamps

Sales & Marketing

Are you learning CNC milling? Here are some tips and tricks to improve and optimize your CNC workflow, from work preparation to end mill selection.

Roldan Descamps

Sales & Marketing

This guide will help you get your feeds and speeds right on your CNC machine, with beginner and advanced chipload values. It will also deepen your understanding on this technical aspect of CNC milling.

Maxime Gravet

Product Engineering

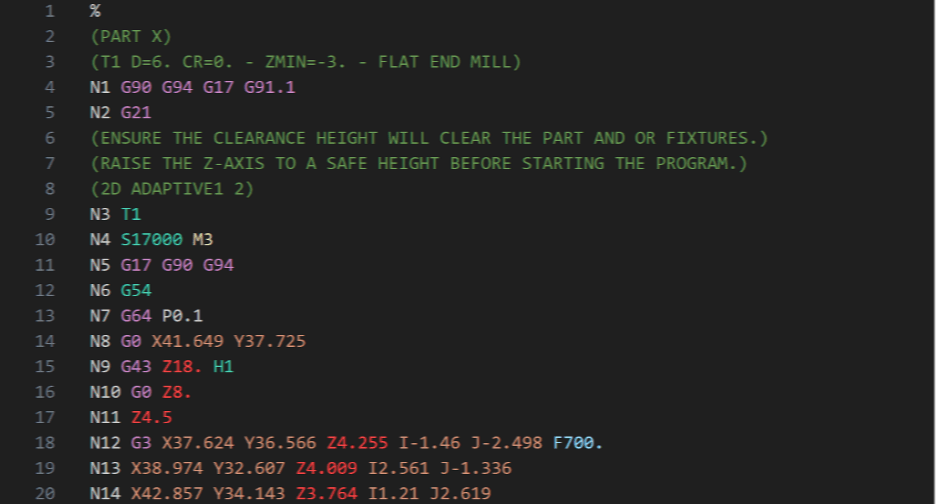

In order to create a G-code from your CAM software and make it compatible with your Mekanika CNC machine, you need to choose the right post-processor.

Maxime Gravet

Product Engineering

This guide will take you through the criteria you should consider when selecting the proper end mill for your machine, depending on your project. It lists the different characteristics you should look for, as well as the existing shapes and format you could use.

Maxime Gravet

Product Engineering

In this detailed CNC milling operation guide, we take you through the most common operations in Fusion 360, helping you to choose the proper one for a specific intent, and to set it correctly.

Martin Duchêne

Product Design

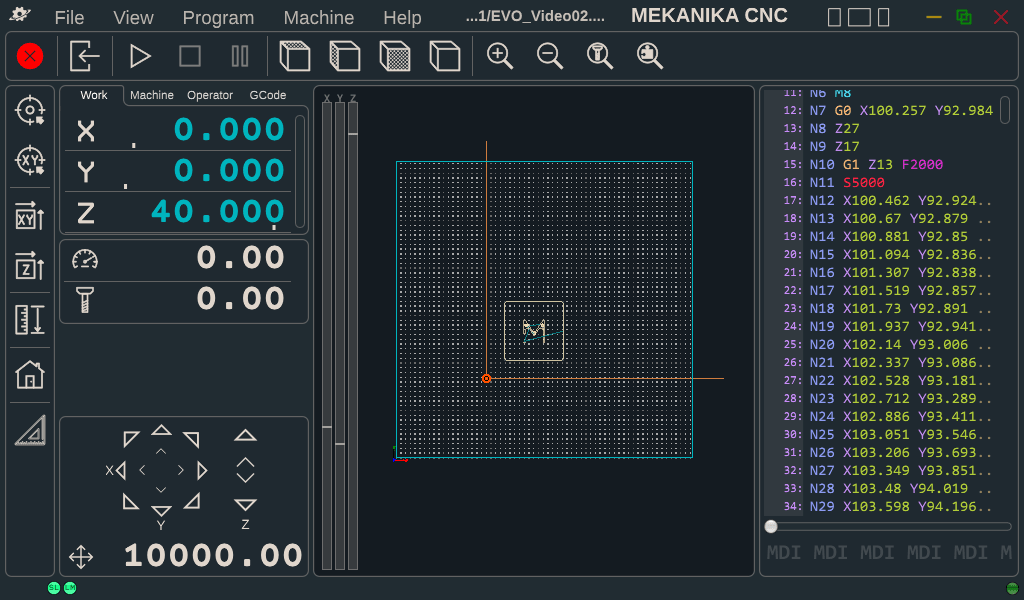

Learn everything about the CNC control software we use: PlanetCNC. From its interface to how to use it on a Mekanika CNC milling machine and its keyboard.

Maxime Gravet

Product Engineering

In this video, you'll learn how to correctly set up your CNC milling machine for machining from a G-Code file.

Martin Duchêne

Product Design

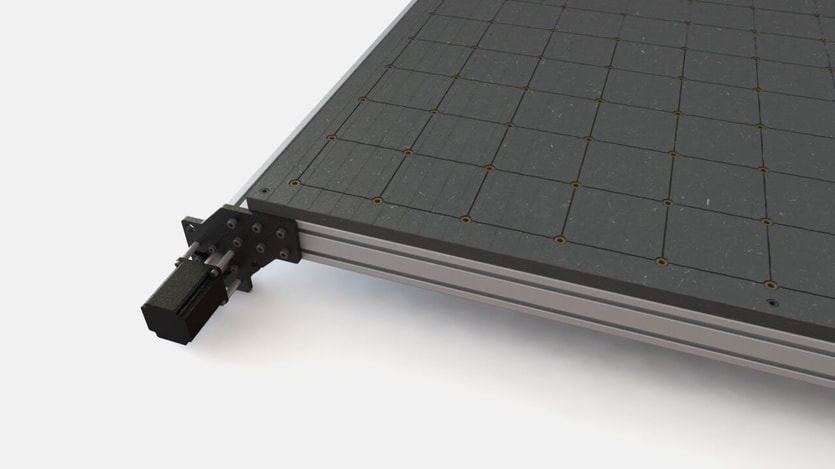

This article helps you choose the ideal spoilerboard for your CNC machine, exploring options from basic wooden boards to advanced setups like vacuum tables. It breaks down each type's cost, durability, and ease of use, guiding you to make an informed decision based on your specific needs and experience level. Perfect for both beginners and professionals, the article ensures you pick a spoilerboard that fits your CNC projects.

Roldan Descamps

Sales & Marketing

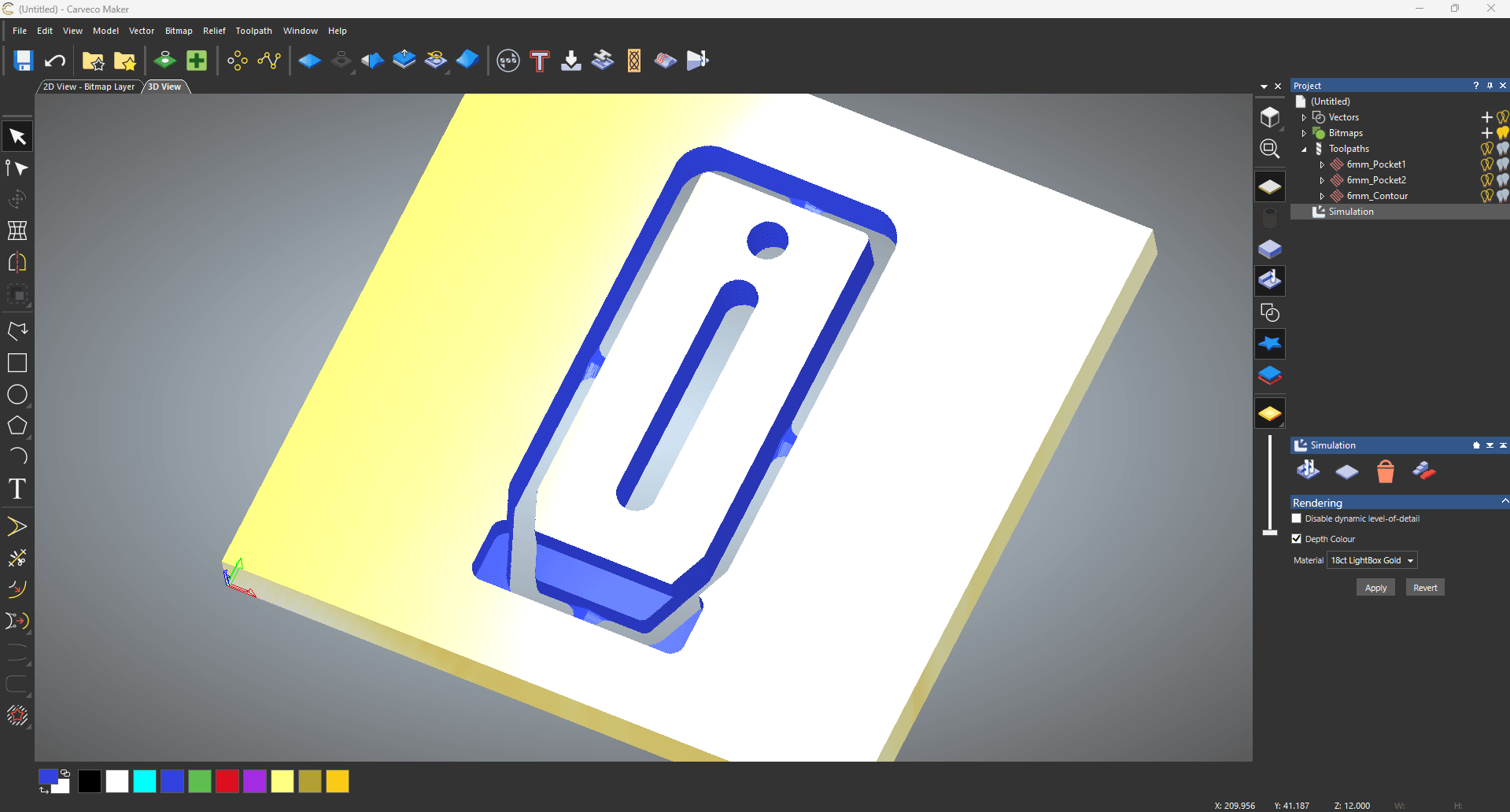

Learn how to create your project and generate a G-Code from Carveco to easily machine your parts on a CNC milling machine.

Quentin Liard

Customer Support