WE BELIEVE IN OPEN SOURCE

Mekanika is an open project where we believe in the power of knowledge sharing and collaborative design. This catalogue was created to make our open-source documentation even more accessible, allowing you to find all the resources necessary to build or modify our machines by yourself.

What kind of tools are we talking about?

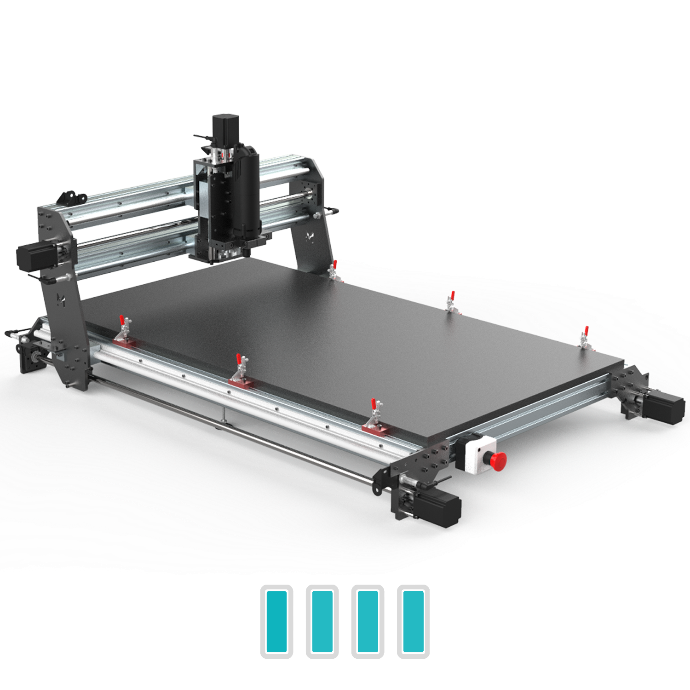

Our open source catalogue is mainly composed of tools and machines that allow you to produce or transform something, but it also contains simple mechanical assemblies such as workbenches or movable furniture.

BEGINNER

- - Simple assemblies

- - Mechanical parts only

ADVANCED

- - Complex mechanical assemblies

- - Moving parts or mechanisms

EXPERT

- - Complex mechanical assemblies

- - Integration of fundamental electrical or electronic components

MASTER

- - Machines composed of moving parts and embedded electronics

- - Requirement for automation or software control

"Design global, manufacture local"

This slogan of the new model of open manufacturing is at the core of our design methodology. We aim at creating tools or machines that can be manufactured and assembled locally, anywhere in the world. In order to achieve this, we constrain ourselves to certain design principles that are explained below.

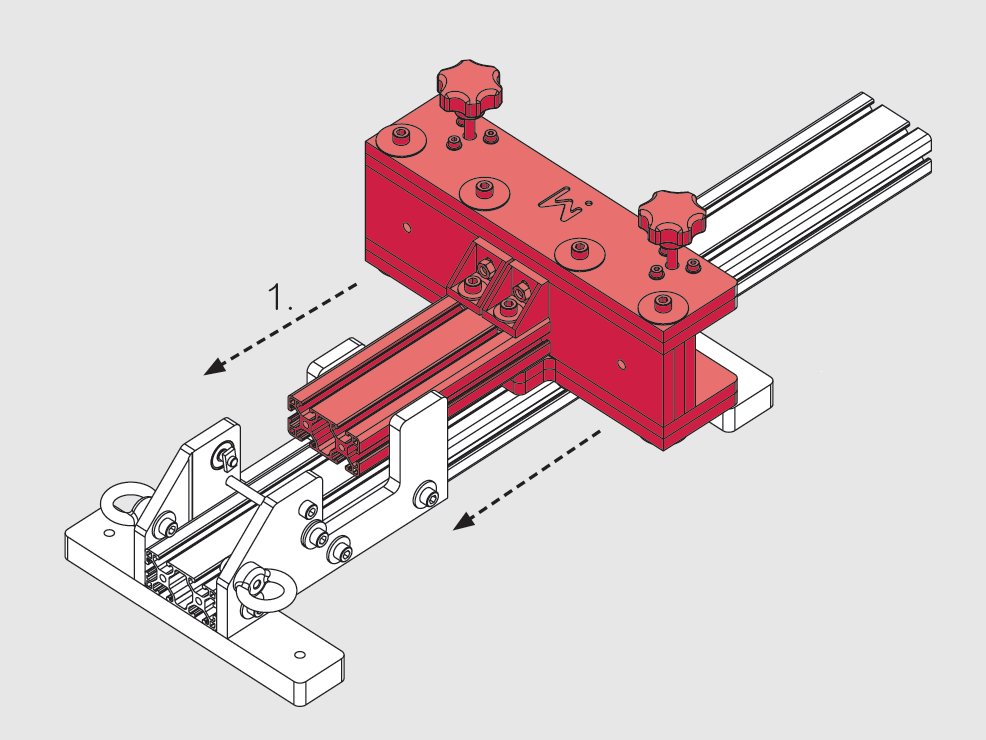

A modular approach

In a modular approach to product design, the product is viewed as a system. A system can be broken down into several modules. Modules are connected sub-systems of components having a specific function, put together in a way that performs the required task. These modules are themselves composed of various basic parts, which are inter-compatible and can be seen as the “Lego bricks” of our tools.

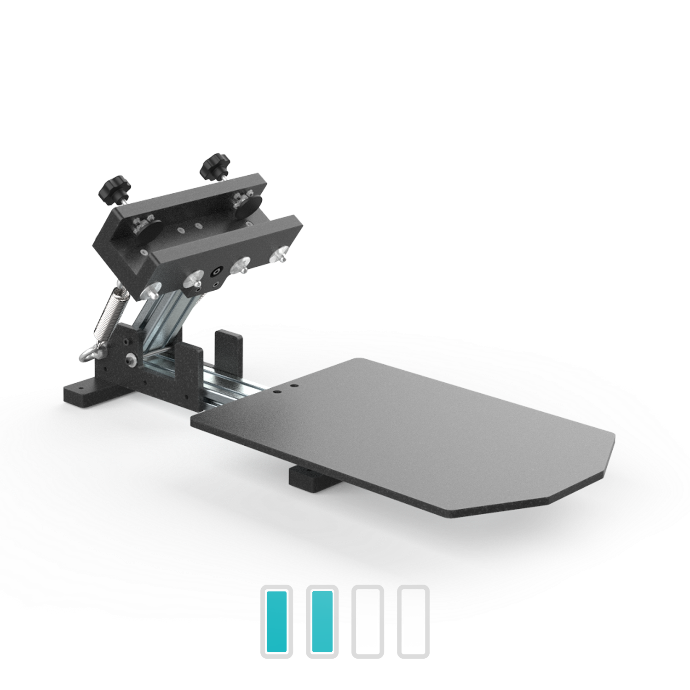

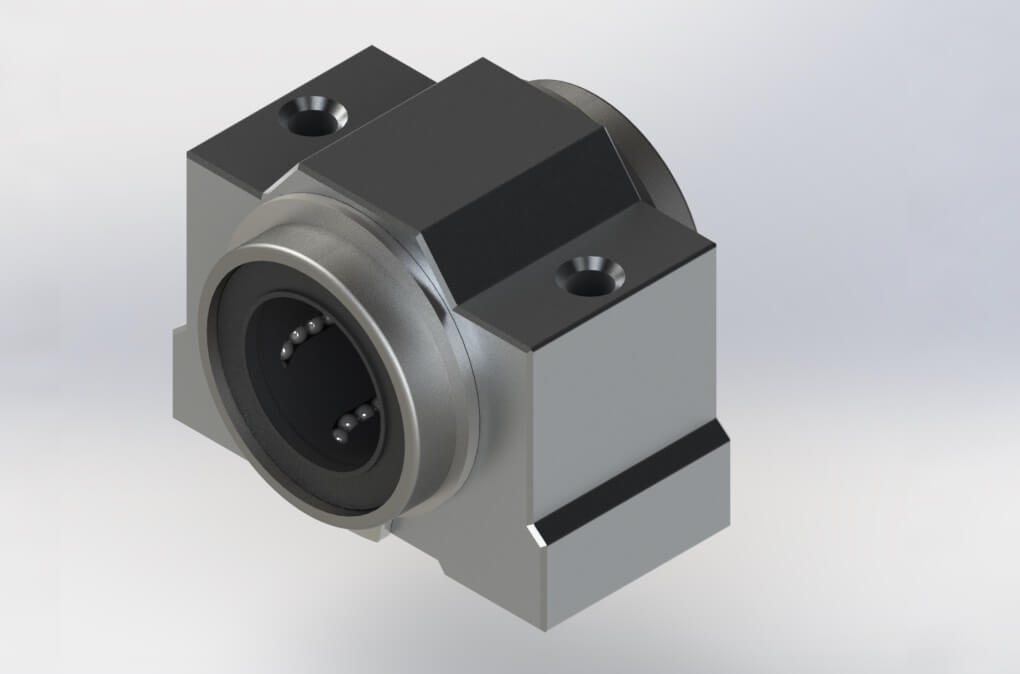

Let’s have a look at our screen printing press as an example. The assembly shows here two modules, having each a specific function: the base and the arm. Both modules use, in turn, several basic parts: aluminium profiles, bearing, brackets, connection plates, etc.

There are many advantages in using such a methodology to design objects, especially tools. Modular design allows to shorten the product design and manufacturing cycles, improves the overall product quality and reliability while facilitating its disassembly.

Thus, modular design can be seen as a key modern design methodology, which not only improves the performance of a product but also plays an important role at the end of the product life cycle. Indeed, modularity is intrinsically a way of designing for disassembly, helping to create non-obsolete products that are more serviceable for the end-user and greatly improving their maintenance and repairability.

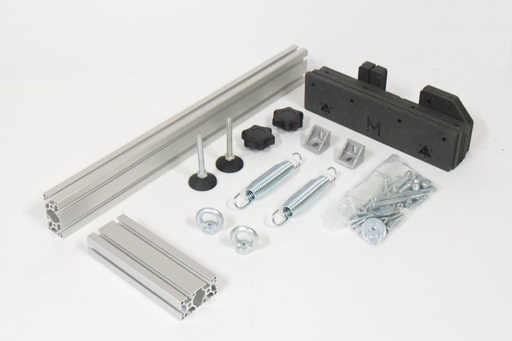

80% standard - 20% specific

We want our tools to be accessible to anyone, regardless of where he/she might live around the globe. To achieve this, we are following two key principles while designing our tools :

1. Most of the parts used in our designs have to be standard components that you could get delivered anywhere.

2. The specific parts used to connect those standard components have to be designed such as they can be manufactured using common FabLab manufacturing technologies.

By common FabLab technologies, we mean all classical woodworking and metalworking tools, but also digital manufacturing technologies, such as laser cutting, CNC milling or 3D printing.

Given that FabLabs will continue to open around the world and on every continent, designing tools in such a way allows people to access small production capabilities easily and gain more control over the life cycle of the surrounding objects.

Open Source & Collaborative Design

The use of the term open source originated with the software but has expanded beyond that sector. It covers now every other open content and form of open collaboration, such as at the development of physical products. It is a model that we decided to embrace by designing products that are freely available to the public and that can be modified and distributed by anyone.

On the other hand, if you already have designed a tool that you would like to share, or modify according to the methodology detailed in this article, please leave us a message using the form below.