End Mills - Boss Complete Set

A complete and affordable set of four 6mm end mills, for advanced craftsmen and hobbyists who want to perform the four fundamental machining operations with their CNC machines. Their special coating limits heat development during milling, minimizing the chance of burning the workpiece and allowing the cutting edge to last three times as long!

Description

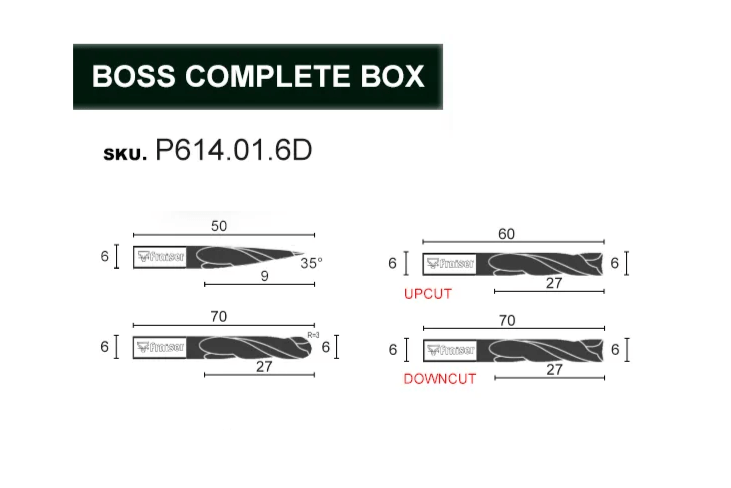

You will get the following end mills, all shipped together in individual protective packages:

- P302.060.6D, an upcut milling cutter with positive helical cutting edges, diameter 6mm, useful cutting width 17mm with high chip discharge

- P303.060.6D, a downcut milling cutter for grooves on coated or delicate materials, 2 negative cutting helixes that push the chips down leaving the top of the workpiece perfect. Diameter 6mm and cutting capacity 27mm.

- P313.060.6D, a ball nose milling cutter with a 3mm cutting radius, for any 3D operation or rounded grooves.

- P212.060.6D, a fantastic 30° single-lip lettering and engraving cutter that allows you to create your own plaques and ideas in a detailed and smudge-free way

WARNING: Collets are not provided in the kit

We also provide a pre-configured library of tools for Fusion360, which will help you get the optimised cutting parameters for these end mills. For those of you that use a different CAM environment. the zip archive contains a text file with all the cutting parameters as well.

Note: Considering that your machine, your end mill stickout, and the material used will be in different conditions than the ones used to determine the parameters, we recommend you use the parameters as ideal values to be reached gradually. Always start with slightly lower values and gradually increase, being ready to intervene if the milling should proceed in the wrong way. We decline all responsibility for the results obtained. Also note that if you are working against the grain of wood, the indicated feed rate values should be multiplied by 0.7. The same factor should be applied if working on Evo, since the machine is less rigid than the Pro and Fab models.